.....

The following procedure was developed to help you get the ailerons mounted without

binding, with the"proper clearances, and with the ability to get them off again:

| 1. |

Trim

the inboard edges of the aileron slot foam cores flush with the sides

of the fuselage. (See "Installing

The Aileron Slot Foam Cores"). |

| 2. |

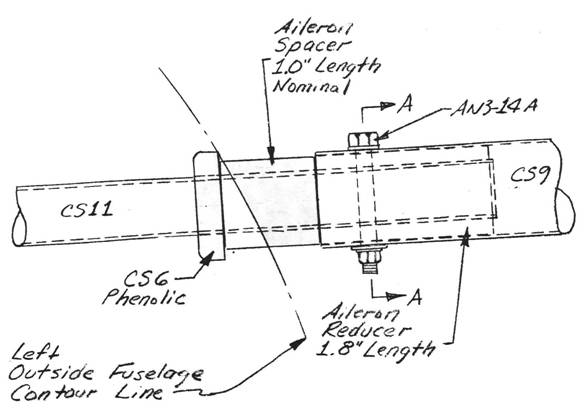

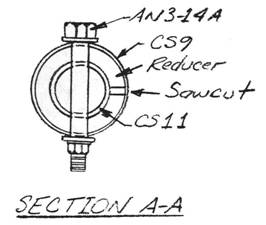

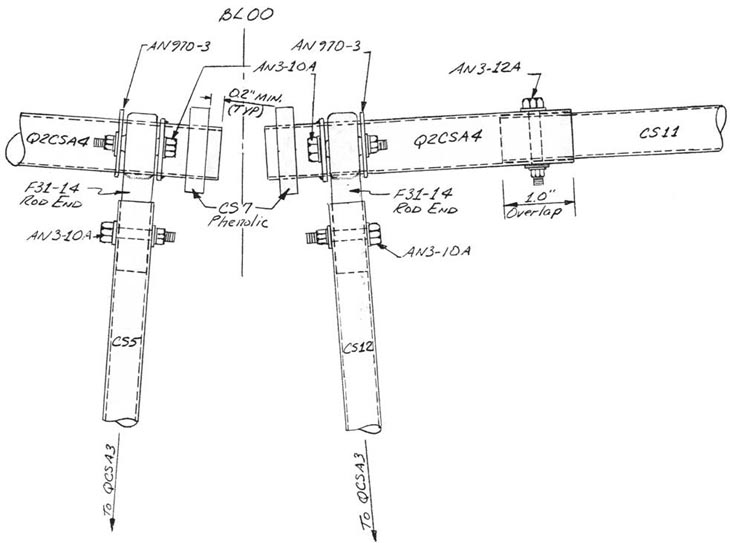

Slip Q2C5A4 over C511; slip C56 over the other end of C511, and slip that same end of C56 into the aileron reducer, which you have already mounted flush with the inboard end of C59, the aileron torque tube looks like a shiskabob doesn't it? |

| 3. |

Slip C57 on the end of Q2C5A4. |

| 4. |

What follows is a very qualitative fitting process. Using at least two

people, dry fit C510, C56 and C57 firmly against the main wing shear web

in the appropriate postions (C510 against inboard end of outboard main

wing trailing edge core, C56, and C57 held in place and check for binding.

Work slowly, correct any binding or clearance problem by modifying C510,

C56, and C57. Please, do one thing at a time. |

|

|

|