Q2 Plans Chapter 6 Page 6-01

- Details

- Category: Q-2/Q-200 Plans

- Published: Thursday, 25 May 2006 15:05

- Written by Quickie Aircraft Corporation

- Hits: 7516

|

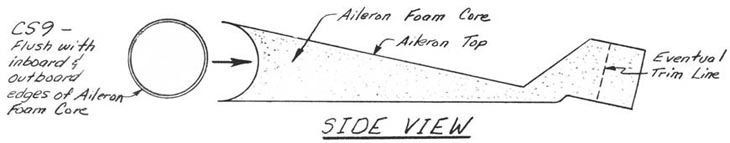

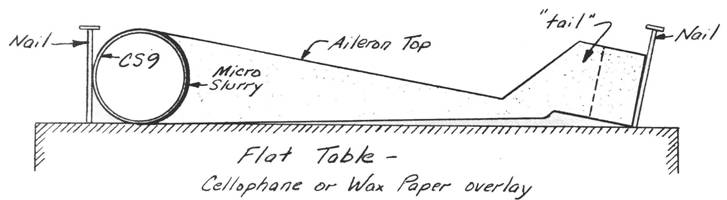

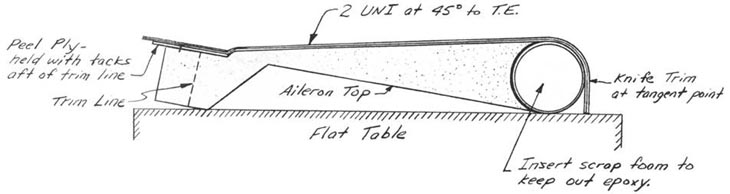

AILERONS, RUDDER, AND ELEVATORS CONSTRUCTION AILERON CONSTRUCTION

..... Both ailerons may be constructed at the same time. These instructions will only cover the construction of the left aileron, but the right aileron is a mirror image. .....Begin by finding CS9, which is a 48" length of 1" O.D. x 0.035" wall 2024T3 Aluminum tubing. You have already hot-wired the aileron foam core, so find it also. The aileron foam core should be trimmed to a 48" length. .....Basically, you will join CS9 to the aileron foam core; sand the joints to remove bumps and joggles; layup the bottom skin; layup the top skin; and, finally, trim the trailing edge after installation on the main wing. .....Begin by sanding CS9,to remove grease, finger prints, and the oxidation layer on the aluminum. Trial fit CS9 to the aileron foam core; mix up some micro slurry, and then join CS9 to the aileron foam core on a flat surface. Use nails to hold the two pieces together. .....Once this combination has cured, sand away all of the bumps and joggles. Next, turn the aileron over and lay it flat on the table, bottom side up. Put Peel Ply along the trailing edge using small tacks to hold it in place. Layup 2 UNI at 45 Deg. to the trailing edge (T.E.) At the leading edge (L.E.) let the cloth drop vertically to the table and knife trim at the point tangent to CS9. Trim the trailing edge to within t" of the foam core trail ing edge. .....When this layup has cured, turn the aileron over and lay it flat on the table. At the leading edge, feather the UNI plies to the foam to remove the joggle. At the trailing edge, sand off the "tail" until you reach the Peel Ply. Remove the Peel Ply, and sand away any bumps and joggles. Layup 2 UNI at 45 deg. to the trailing edge. At the leading edge, overlap a minimum of 0.5" onto the previous bottom layup. At the trailing edge, layup glass to glass. Leave the aileron alone until it has cured to avoid changing the alignment, and then feather the top surface UNI plies to remove the leading edge (L.E.) joggle. . .....Leave the trailing edge untrimmed until after the aileron is mounted on the main wing, so that it can be made to match the trailing edge of the wing. The joggle on the bottom of the ailerons (as well as the joggles on the bottom of the rudder andelevat¬ors) is filled with dry micro after installation of the aileron on the wing or during the finishing phase.   SEE NEXT PAGE FOR DETAILS OF CUTTING AND LAMINATING CLOTH ON AILERONS  |

||||

CONTINUED ON NEXT PAGE |

||||

PAGE

6-1 |

||||