Q2 Plans Chapter 6 Page 6-03

- Details

- Category: Q-2/Q-200 Plans

- Published: Thursday, 25 May 2006 15:05

- Written by Quickie Aircraft Corporation

- Hits: 4880

|

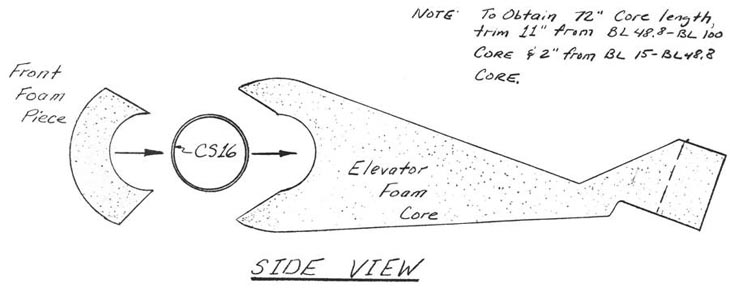

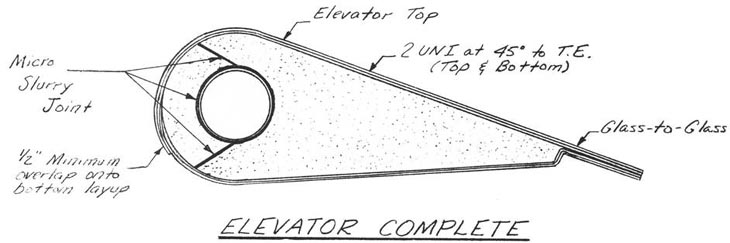

ELEVATOR CONSTRUCTION

..... The elevator construction is very similar to the aileron construction that you have already completed. Reread the AILERON CONSTRUCTION section before proceed¬ing further. .....These instructions cover only the construction of the left elevator, but the right elevator is a mirror image. It is suggested that both elevators be construct¬ed simultaneously. Since the elevator has a tapered chord, BE SURE TO MAKE ONE LEFT ELEVATOR AND ONE RIGHT ELEVATOR. .....Begin by finding CSI6, which is a 72" length of 1" O.D. x 0.035" wall 2024T3 aluminum tubing. You have already hot wired the inboard and outboard elevator cores, so gather these together also. When the cores are joined they should total 6 ft. in length. .....Basically, you will join the inboard and outboard core together, insert CSI6, replace the front foam pieces, sand the combination after it has cured to remove bumps and joggles,' layup the bottom skin, layup the top skin, and final trim the trailing edge after i nsta 11 ati on. .....First, verify that the circular cutout for CS16 hot wired in the foam cores is large enough by putting the cores, CSI6, and the fr9nt foam piece together dry. If the front piece won't clamp up against the core easily, carefully enlarge the cutout for CS16 until it will. The micro slurry will require approximately 1/32 gap. .....Next sand CSI6. Mix up micro slurry paint it both on CS16 and on the foam wherever CS16 comes in contact with foam. Join the inboard and outboard foam cores together with micro slurry insert CSI6; then insert the front foam peice. Do not telescope CS16 into the core by pushing it from one end; this will cause voids in the bond. Instead, it should be inserted all along the span at one time. Use nails to hold everything in place while it cures (see AILERON CONSTRUCTION),and verify that both ends of CS16 are flush with the ends of the elevator foam cores. .....The elevator lamination is 2 UNI bottom and top at 45 deg. to the trailing edge, just like the aileron. Measure the elevator foam cores and then cut the UNI cloth to the proper size. More than one piece of UNI will be required to cover the entire 72" elevator span. Where the UNI pieces join, no overlap is needed, (i.e. butt joint is OK) but stagger the joints on Ply #2 so that the foam along the butt joint line is covered. Lay up these plies exactly like yo_ did on the ailerons. Don't forget the foam scraps in the end of CSI6. Do not trim the trailing edge until after the elevators are mounted on the canard.   |

||||

END OF CHAPTER |

||||

PAGE

6-3 |

||||