Q2 Plans Chapter 5 Page 5-01

- Details

- Category: Q-2/Q-200 Plans

- Published: Friday, 26 May 2006 15:05

- Written by Quickie Aircraft Corporation

- Hits: 7523

|

HOT-WIRING INTRODUCTION

..... In this section, you will hot-wire the foam cores for the wing, canard, rudder, vertical fin, ailerons, and elevators. .....Begin by reviewing the COMPOSITE MATERIALS EDUCATION chapter. That means more than just glancing through the chapter; study it thoroughly until you can recite it in your sleep. .....Hot-Wiring is not difficult, but will require two people and a precise, careful approach to obtain good quality cores. .....Before we continue, let's emphasize a few important points that you have already read in the COMPOSITE MATERIALS EDUCATION chapter:

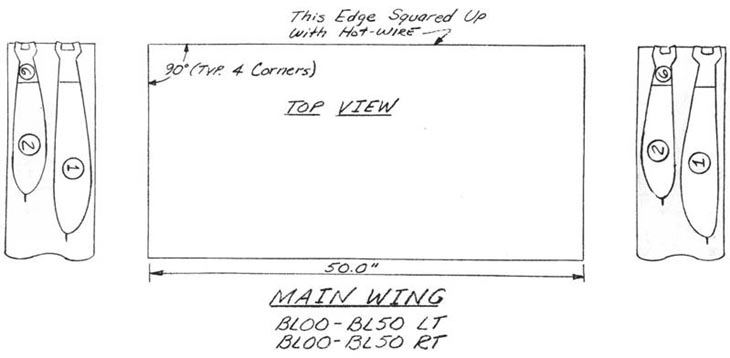

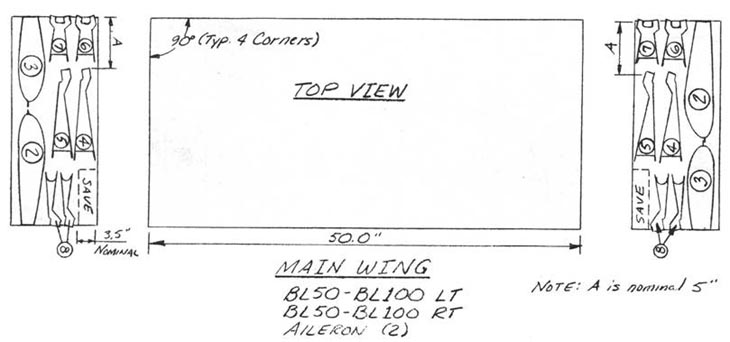

MAIN WING CORES

..... Find the two 10" x 24" X 96" nominal dimension blocks of polystyrene foam. .....Using straightedged trim templates, square up three sides of one block to generate a core 50.0" long. The fourth edge (along the 50" side - see sketch) can remain scalloped. The sketch shows the positioning of the appropriate templates on each end of the block. Note that the sketch end views are oriented to duplicate the "picturell one sees looking at each end of the block. .....The second block is prepared identically, except the fourth side along the 5011 edge needs to be squared up also. Follow the layout sketch to obtain the appropriate cores. Be sure that templates 2 and 3 can face each other without running out of width on the block. .....The trailing edge of each template, unless otherwise indicated, must be lined up with the edge of the polystyrene foam. This gives the core the proper geometry for assembly into the main wing female jigging templates. .....The aileron cores must be trimmed on either end after hot-wiring to 48" length. Both the Trailing Edge Foam Cores and the Aileron Slot Foam Cores (outboard) are cut considerably oversized, and will be trimmed to the proper length during installation.   |

||||||||||||||||||||||

|

||||||||||||||||||||||

PAGE

5-1 |

||||||||||||||||||||||