Q2 Plans Chapter 3 Page 3-9

- Details

- Category: Q-2/Q-200 Plans

- Published: Sunday, 28 May 2006 03:05

- Written by Quickie Aircraft Corporation

- Hits: 6440

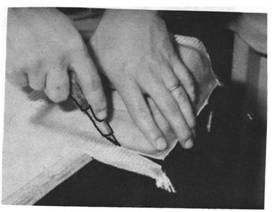

STEP 7: SQUEEGEEING ..... Squeegee out excess epoxy. This involves drawing a plastic or rubber squeegee over the layup as shown. Plastic squeegees (scrapers) are available at any paint store and included with the kit. If excess epoxy exists, it will be pushed off the edge of the piece. Remember, excess epoxy is much better on the floor than on the airplane. It is possible to squeegee too hard and make the layup too dry. If this occurs, the surface will appear white, indicating the presence of air. If this occurs, wet the cloth by painting on a little epoxy and stippling it down into the layup. The best quality layup is obtained if each layer of a multilayer layup is squeegeed. The excess epoxy which is pushed off the edge can be recovered and returned into the cup. This is easily done by catching the epoxy on the squeegee and scraping it on the side of the cup. .....The finished layup should appear smooth and green so that the weave of the cloth is clearly visible, but not so dry that any area appears white in color. If you've done an excellent job, the weight of resin will be about 2/3 of the weight of cloth used. .....To check if there is too much epoxy in the layup, pull a squeegee across the surface, stopping before you reach the edge. Lift the squeegee up and look for a large "ridge" of epoxy where the squeegee stopped. The ridge under the top ply indicates that the layup is too wet and you should spend time with the squeegee to remove epoxy off to the sides. .....Don't hesitate to use your stippling roller or brush on an area after squeegeeing. Some places are not suited to the use of a squeegee and the dry brush or roller must be used to expel the excess epoxy. On a given layup, about 1/2 of your time should be spent squeegeeing or stippling.  STEP 8: GENERAL INSPECTION

STEP 9: PRELIMINARY CONTOUR FILL ..... Certain areas, like along the trailing edge (see cross section views) require a dry micro fill. It is preferred to apply this fill within 2-3 hours of finishing the fiberglass layup. However, where the micro filler obscures the structure underneath, FAA inspection should be completed before dry micro filling. Areas like the trailing edge where the structure can be inspected from the other side should be filled while the layup is still tacky (within three hours of the layup). If you wait until the layup cures, you will have to sand the fiberglass surface to a dull finish before applying the micro. So, mix up a "dry" micro mix and trowel it into low areas while the layup is still wet, and save the work of sanding where feasible. STEP 10: CLEANUP ..... Brushes can be used two to four times if after each layup they are washed with soap and water. Wipe excess epoxy off with a paper towel. Wet the brush and work soap into all fibers by mashing it into a bar of soap (Lava brand is best). Rinse with hot water and repeat 3 times. Be sure they are dry before next use. We generally use a cheap brush (approximately $2.00 to $4.00 per dozen) and discard after two or three layups. Clean squeegees the same way. .....If you use skin barrier cream (Ply No.9), the epoxy and cream will wash off easily with soap and water. When you get epoxy on unprotected skin, Epocleanse is used to remove the epoxy. Both of these products are available. Once you are sure your skin is clean, wash again thoroughly with soap and water, even if your hands were protected with plastic gloves. If you get epoxy on tools or metal parts, clean them with acetone or MEK before the epoxy cures. . .....The only good way to protect your clothing is not to get epoxy on anything that you care for. Use a shop apron and don't make layups in good clothing. A surplus flight suit or other cheap coveralls are a good investment. .....You may feel that layups are messy work after your first experience with them. However after you've done several, you will have learned not to wipe your hands on your clothing (keep a roll of paper towel's handy), not to scratch your ears, eyes, etc. during the layup. If your tools and work area are clean and organized well and you are disciplined with the epoxy, the job can be less messy than working with other materials. STEP 11: KNIFE TRIM ..... When a layup is wet, you can only scissor trim to within about 1/4 inch without disrupting the fibers in the ply. An easy clean trim can be obtained by waiting three to five hours after the layup. At this time, the laminate is firm enough to support the cloth from fraying, yet soft enough to cut easily with a sharp knife. This "knife trim" stage is the optimum time for edge trimming with ease and accuracy. Take a sharp, single-edge razor blade or X-Acto knife and trim the edges with a motion downward toward the edge. Experience will help you determine the correct time in the curing cycle for optimum knife trimming.  ..... In the plans, when "knife trim" is called for, this assumes the three to four hour wait, even though not specifically stated. Don't fall apart if you miss the knife trim stage and have to trim the fully cured glass. If you wait until the layup is completely set, then saw along the edge with a coping saw, dremel, bandsaw, saber saw, etc. Smooth the edge with a sanding block. When trimming a cured edge, be careful of the "needles" (sharp protrusions of glass-frayed edges supported with epoxy). .....The needles can be avoided by returning three hours after the layup to make the knife trim. Knife trim time varies with temperature: about six hours at 60 degrees and one hour at 90 degrees. OTHER SURFACES ..... Surface preparation (step 3 of the basic glass layup) varies with the material that you are laying up over. The layup over foam was covered in detail in step 3. To prepare a cured glass surface for layup, the cured surface must be sanded to a completely dull finish with 36 to 60-grit sandpaper. If any of the glossy surface remains, an incomplete bond results which is weak. Better yet, use peel ply as described later, Micro slurry should not be applied to glass surfaces being bonded; this weakens the joint. Wood requires no special preparation for bonding but should be free of grease, oil, paints, and varnish. Sand wood surfaces with 36-grit sandpaper before layup. Metal bonding is not relied upon for strength but | ||||

| ||||

PAGE 3-9 | ||||