Q2 Plans Chapter 3 Page 3-11

- Details

- Category: Q-2/Q-200 Plans

- Published: Sunday, 28 May 2006 03:05

- Written by Quickie Aircraft Corporation

- Hits: 5711

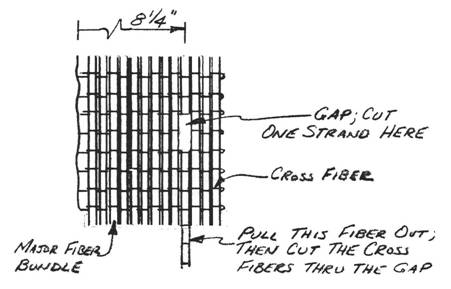

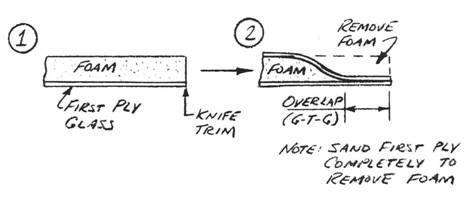

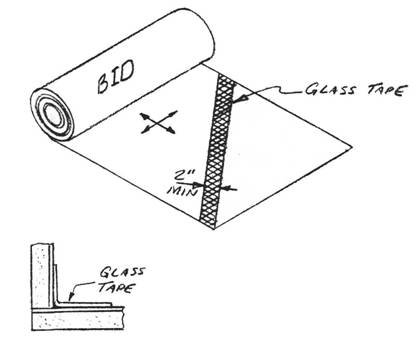

CUTTING THE UNI SPAR CAPS ..... The spar caps used in the main wing, vertical tail, and canard, are strips of UNI cloth that you will cut from the roll provided in the kit. Begin by unrolling the roll on a long, flat surface. The example to be used here will be a spar cap A that is 8" wide by 50" long. You would measure a 8-1/4" wide piece (to allow for frazzling of the edges) by 50" long, with the fiber orientation running along the 50" edge. .....The technique is one of finding the one strand that is at the edge of the 8-1/4" width, cutting it, and then pulling that whole strand the length of the spar cap to remove it. You will now see a clearly visible gap in the UNI cloth where that one strand used to be. Now, using an Exacto knife or razor blade, cut all of the cross fibers along that gap, thus severing the spar cap from the rest of the roll. .....Carefully mark the cap with a centerline (in this case at the 25" point, mark it with the 1 etter A and roll it up to keep dirt out of the fibers. When you next unroll it, you will probably find that the edges are frazzled. As long as you don't reduce the width below the original callout (in this case 8") you may pull off strands that are frazzled. Be carefull to only pull loose one strand at a time or else the whole spar cap will start coming apart!  GLASS-TO-GLASS ..... In order to improve the rigidity of a part, you will occasionally be asked to perform a glass-to-glass layup, sometimes abreviated as GTG. .....The example shown here is a glass-to-glass layup on a bulkhead. Begin by glassing one side of the bulkhead as usual. Next, having turned the bulkhead over after curing to prepare the other side for glassing, you will remove foam with a smooth transition so that your next layup will butt up against the previous glass layup. .....The amount of "overlap" necessary varies with the loads. On bulkheads, use a minimum of 3/8", on the trailing edges of ailerons and elevators use 1" minimum, and on the trailing edges of the wing, use 3/8" minimum.  PHENOLIC BONDING TAPES ..... Quite often during the construction of your Q2, you will be asked to use glass tapes to join two pieces together. .....A glass tape is a strip of BID cut at 45 degrees which is used to lap up onto both surfaces that are being joined. For proper strength, the tape should be at least 2" wide.  QUALITY CONTROL CRITERIA INTRODUCTION..... One of the unique features of the glass-foam-glass composite construction technique is your ability to visually inspect the structure from the outside. The transparency of the glass/epoxy material enables you to see all the way through the skins and even through the spar caps. Defects in the layup take four basic forms: resin lean areas, delaminations, wrinkles or bumps in the fibers, and damage due to sanding structure away in finishing. Resin lean areas are white in appearance due to incomplete wetting of the glass cloth with epoxy during the layup. DRYNESS CRITERIA ..... Pick any 6"x6" square in the layup in the critical area. Assess carefully if any evidence of air in the layup is present (white flecks, bubbles, air at the foam face). If the dryness is more than 10% of the area, the part MUST be rejected. Reject or repair any evidence of dryness or voids in the trailing edge or leading edge overlaps. Better yet, do an adequate inspection with good light before cure when it's easy to fix. If in doubt on overlaps be sure to stipple in enough epoxy. .....Delaminations in a new layup may be due to small air bubbles trapped between plies during the layup. The areas look like air bubbles and are distinctly visible even deep in a cured layup. Small delaminations, or bubbles up to 2-inch diameter, may be filled with epoxy by drilling a small hole into the bubble and filling the void with epoxy. .....When making a layup, do not be concerned if the brush occasionally sheds a few bristles; these do not need to be removed. If the bristle count exceeds about 10 per square foot, change your brush and remove bristles. .....Occasional sanding through the weave in the first skin ply is not grounds for scrapping the part. Care should be exercised in areas, such as the skin joints, not to weaken the structure in pursuit of an optimum finish. An excess of resin (wet) will make your airplane heavy and does weaken the layup, but usually not enough to reject the part for strength reasons. BUMP/JOGGLE/DIP CRITERIA .....The best way to check this is to lay a 12-inch straightedge on the part spanwise. Move it allover the surface in the critical areas. If you can see 1/16" gap in any area, the part must be repaired. It is best to repair or beef up lumpy areas even if they meet this criteria. Better yet, do a good job in core preparation and use your squeegee well in the layup to avoid the lumps in the first place. | ||||

| ||||

PAGE 3-11 | ||||