Q2 Plans Chapter 3 Page 3-13

- Details

- Category: Q-2/Q-200 Plans

- Published: Sunday, 28 May 2006 03:05

- Written by Quickie Aircraft Corporation

- Hits: 6504

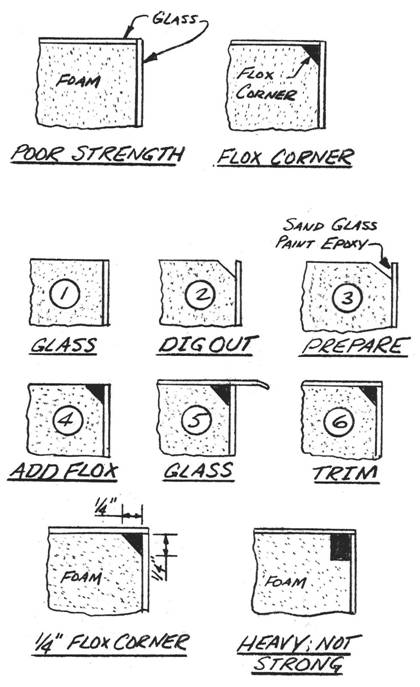

..... In some areas a sharp corner is desirable and maximum strength isn't required. In these areas a flox corner is used. A simple unsupported glass corner has very poor strength. To strengthen this corner, a triangle of flox is used to bond the glass plies together. The flox corner is done just before one glass surface is applied for a wet bond to one surface. The other glass surface has to be sanded dull in preparation as shown.  HEALTH PRECAUTIONS SKIN PROTECTION HEAT DEFORMATION AND CREEP ..... Several builders have had flying surfaces warp or bend due to being poorly supported until fully cured. Do not hang or support them at each end for long periods as they may "creep" or slowly deform. Store them leading edge down with support in at least three places. Your surfaces can be better protected against "creep" if you post-cure them. Sailplane manufactures do this by putting the entire airplane in an oven at 160°F. You can do it as follows: After you have painted on the black primer put the wing or canard out in the sun. Be sure it is well supported in at least three places along its span. At noon a black surface can reach 140 to 180°F. giving it a relatively good post-cure. After the post-cure, the structure is more stable for warping or creep. If you have a wing or canard that is twisted wrong, apply a twisting force in the opposite direction before and during the post-cure (weights applied to boards,Bondoed or clamped to the surface can be used). Remove the force only after the surface has cooled. A 200 ft-lb torque (50 lb weight on a 4 ft arm) applied twice, once while the top surface is post-cured and once for the bottom, surface, can twist your wing or canard over one degree. The twist correction will be permanent and will stay as long as the surface remains cool (below the postcure temperature). This is generaly referred to as the heat-deformation characteristic of the epoxy. If it is room-temperature cured only, it will soften above 140°F. But if post-cured it will not soften until over 160°F. Heat for post-curing or for intentional deforming can be applied by other means such as heat lamps, hair dryers or electric radiant heaters (house-hold type), however this is generally not recommended, since it is too easy for the homebuilder to get the part too hot and ruin the part. The foam is damaged above 240°F. If you want to use these heat sources, do so by applying the heat very slowly and checking the temperature often by placing your hand on the surface. If you can hold your hand on the surface five seconds without pain, the temperature is okay-three seconds is too hot.

AIRCRAFT MEASUREMENT REFERENCE SYSTEM .....To ease the engineer's task of defining where things go in these odd-shaped gadgets called aircraft, a fairly standard system of references has been developed. Fortunately the Q2 is so simple that an eleborate measurement system is not necessary. It is, however, convenient to use the standard terminology for reference occasionally and you should be familiar with its meaning.

| ||||

PAGE 3-13 | ||||