SURFACE FINISHING INTRODUCTION

.....Finishing the composite airplane is more important than simply obtaining an attractive paint job. The finish on a composite aircraft serves to protect the structure from deterioration due to ultra violet radiation (sunlight). The finishing materials also give the airplane its final aerodynamic shape. Using the proper materials and techniques, the finishing process is pleasing (both esthetically and aerodynamically), and provides for long maintenance-free service. Use of sub-standard materials can limit the life of the finish, result in an overweight airplane, and even limit the service life of the airframe. Sanding is done frequently during-the finishing process and extreme caution must be exercised to avoid damag¬ing the structure. A poorly executed finishing job can destroy the structural integrity of the airframe. Even the finished color of the composite aircraft can effect its structure. The finishing process is as important to the structure of the composite airplane as basic materials and techniques used in fabrication are. Proper techniques must be adhered to for safety as well as to obtain an attractive airplane.

.....The Q2 is sensitive to weight growth. You may easily add 50 pounds during the finishing process if you try to finish the entire aircraft to sailplane standards (smooth, wave-free surfaces).

.....There is one part of the aircraft that must be finished to a smooth and wave-free surface - the canard. We have found that unless the canard is smooth and wave-free, serious degradation of performance and flying qualities results. This section will tell you how to obtain a smooth and wave-free finish on the canard.

.....The rest of the airplane, in order to keep it as light as possible, should be sanded with very little filling, then primed. and then painted. This will allow some of the fiberglass weave to remain showing, but your Q2 will still look good.

.....Remember, build it light and finish it light; every pound of weight that you save during the construction and finishing will make the aircraft much more fun to fly in the coming years.

FINISH COLORS AND HEAT

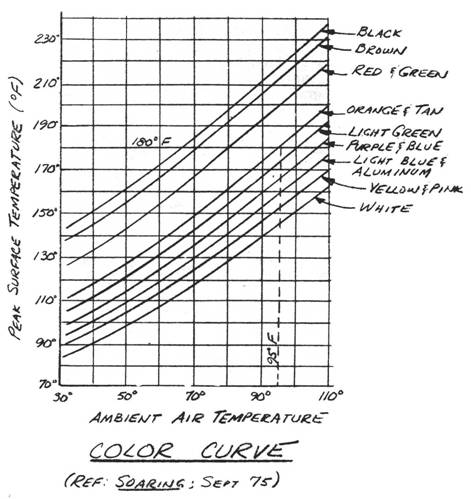

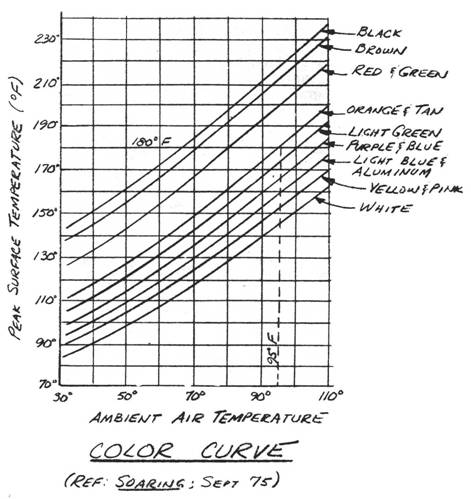

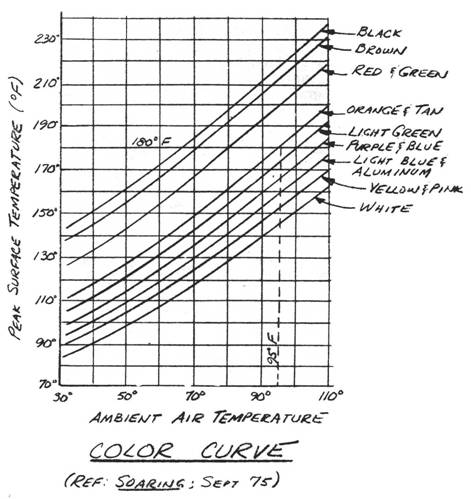

.....The materials used in amateur-built composite airframes are predominately epoxy resin systems with fiberglass reinforcement over a variety of plastic foam cores. The epoxies and the foams are all sensitive to high temperatures. Some epoxies, cured at elevated temperatures, retain their physical strength to temperatures not found outside an oven. Others, including most room temperature curing epoxies such as the Safe-T-Pox system, soften and loose their rigidity at only moderate temperatures. The common plastic foams are also heat sensitive and tend to soften and (some) swell with moderately elevated temperature. Elevated temperatures could potentially cause a softening of the fiberglass load bearing material, a swelling of the foam core, and general distortion of the airframe. To achieve elevated temperatures you would have to bake your airplane or find some other means of heating it. The sun is a potential source for this heat. In still air, on a hot sunny day it is possible to obtain surface temperatures that approach 250°F. The color of the surface determines how much solar heat it will absorb. White surfaces absorb very little (10%) of the sun's heat while a black surface (95% absorbsion) will heat up tremendously. The accompanying graph shows the relationship between color and surface temperature. White has been choosen as the standard color for fiberglass sailplanes to preclude any possibility of excess temperature due to solar heating. The same criteria apply to the Q2, and white is recommended. Trim colors in less-critical areas such as the fuselage, vertical tail, and the underside of wings and canard, can be other than white. Dark trim colors are definate1y not recommended on the upper surface of wings and canard! If you would like further information on the subject read the September 1975 issue of Soaring magazine.

TOOLS AND MATERIALS

..... The tools and materials used in finishing the composite airplane are simple and straight foreward. A low density microsphere/epoxy mixture (dry micro) is used for coarse filling requirements. Automotive type polyester body fillers (Bondo) are very heavy and not recommended as a primary aircraft finishing material. Medium to light surface filling (less than .030") is done with a light weight polyester spray (or brush) filler/primer called Feather-Fill. Feather-Fill is noteworthy for its ability to fill medium thicknesses in a single spray or brush coat and for its easy sanding to a smooth surface. Dupont 705 dark gray laquer primer/surfacer provides an effective ultra violet radiation barrier with its 15% carbon-black content as well as an excellent finish sanding surface in preparation for the finish paint. The actual finish paint type is largely a matter of the builder's personal preference. Automotive finishes in laquer, enamel, acrylic 1aquers, acrylic enamels, and the polyurethanes are all acceptable. We find the acrylic laquer is easy to work with, easily patched, and readily polished to a high gloss.

.....The enamels and acrylic enamels are low cost and easy to apply; however, they are not readily repairable if chipped. The polyurethane finishes offer the best gloss for the longest life, but they are high cost and virtually impossible to repair. There is a polyester paint, known as Prestek, commonly used in sailplane circles to achieve a glass-smooth finish, but it is heavy, requires a tremendous amount of work to get a high gloss finish, and chips easily (brittle).

.....Sanding will occupy a large percentage of the time spent finishing the composite aircraft. Sandpaper in 36 to 60-grit, 100-grit, 220-grit, and 320-grit roughnesses will be used. Standard 9"xll" sheets are the most versiti1e. Use a good quality aluminum oxide, or silicon carbide sandpaper. Don't waste your money on the cheap flint-type sandpapers. Power sanders are not recommended; it is too easy to damage the structure while using them. Hard (wood) and soft (foam) sanding blocks and the sanding spline shown will be,your primary finishing tools. A paint spraying setup will be desirable for feather fill, U.V. barrier primer and finish painting. Some hand brushing of feather fill and U.V. primer can also be done. |