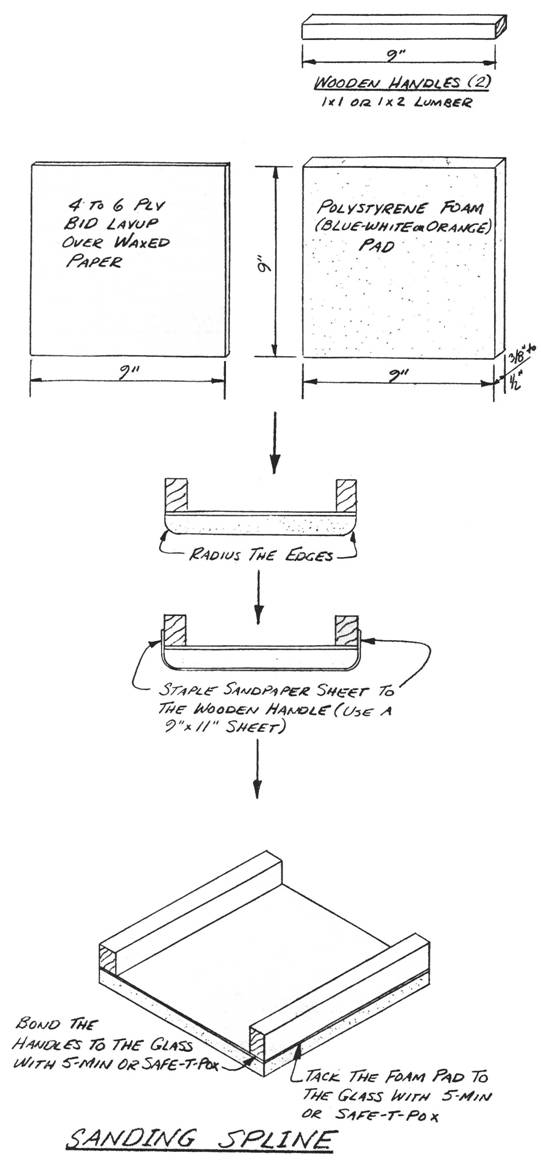

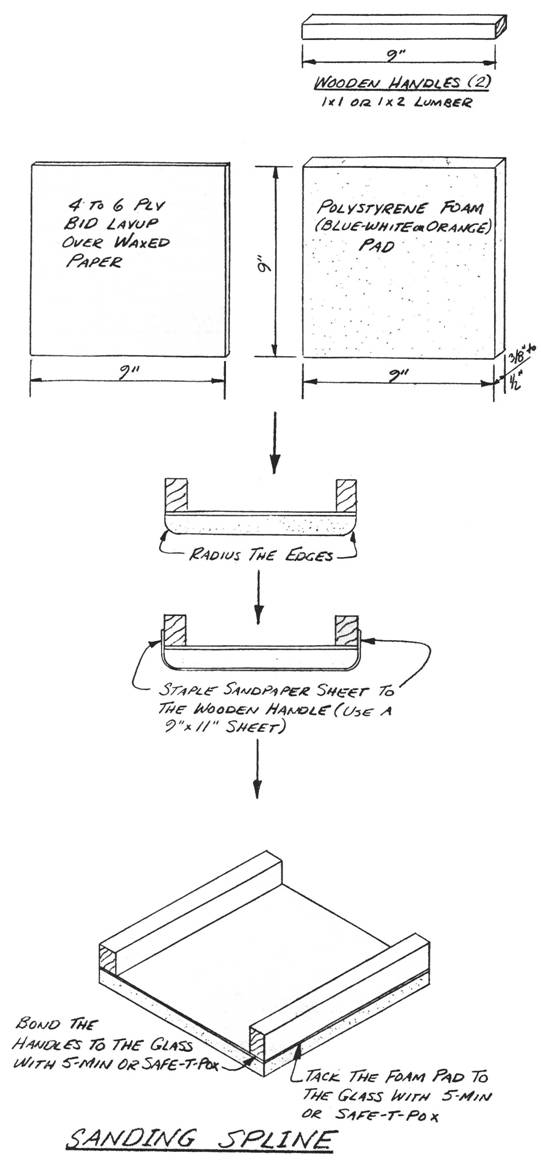

.....The sanding spline is a finishing tool common to the sailplane industry. It is an easy tool to make and does an excellent job of contouring. You may find it handy to make two, one for coarse grit sandpaper and one for medium or fine sanding. The spline is an easy tool to use but it may require your close attention at first. The spline is always held with handles parallel to the leading edge of an airfoil surface (wing, canard, etc.) as shown in the sketch. The sanding motion is on a diagonal to the leading edge while the spline's handles are held parallel. This takes a little getting used to but becomes second nature after a little practice.

THE FINISHING PROCESS

..... Finishing the composite airplane is a five-step operation. Repairs or rework of structure must be completed first, before the obscuring finish is applied, and final structural inspections must be complete. Second, coarse contour filling is done with microspheres/mixed with epoxy (dry micro) as required in areas requiring .03 inch to .20 inch of fill. Any exceptionally gross filling (over .20 in) is also accomplished at this stage using a foam filler. The initial contour sanding begins with the cured microsphere filler, and exceptional caution must be exercised to avoid damaging the structural skins while sanding. Third, featherfill is applied to fill medium sized surface defects up to .03 inch, and as a general fill of the glass surface weave. The fourth step is the application of an ultra violet barrier primer. Fifth, the final finish paint is applied.

.....The following sketches are descriptive of the finishing process and its potential pit falls. The sketches use an exaggerated scale to show details more cl early. STEP ONE: INSPECTION/REPAIRS

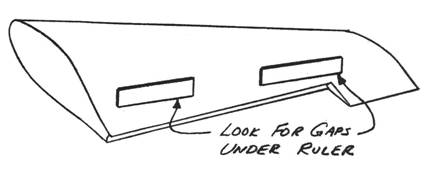

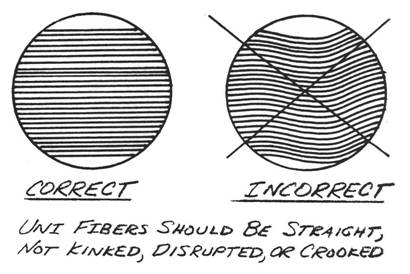

..... Before you begin finishing, the entire structure must be airworthy. You can hide poor workmanship from your own eyes and from the inspector who will finally approve your first flight, but you can't fool mother nature! All structure must be sound before finish materials are applied. The following sketches are a review and clarification of the quality control criteria found in Chapter 3 . Each airplane must have a thorough inspection and required repairs completed as the first step in finishing. The best way to inspect the structure for bumps or dips is to place a 12" ruler on the wing or canard span-wise, as shown. Gaps under it approaching 1/16" height must be repaired.

CONTINUED ON NEXT PAGE |