Q2 Plans Chapter 3 Page 3-20

- Details

- Category: Q-2/Q-200 Plans

- Published: Sunday, 28 May 2006 03:05

- Written by Quickie Aircraft Corporation

- Hits: 7795

PRACTICE LAYUPS FLAT

LAYUP

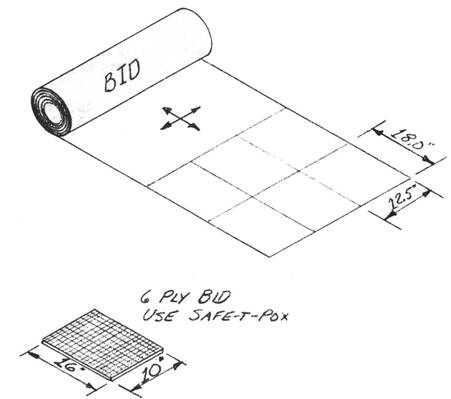

.....Laminate the six plies on top of the waxed paper. Try to do your best job of stippling and squeegeeing

so that the plies are completely wetted but not full

of excess epoxy. Let the layup cure to knife trim, about four hours. Carefully mark a 10 inch by 16 inch rectangle and knife trim the layup to that size using

a sharp razor blade or trim knife. Allow the layup to cure completely. If you forget the knife trim, cut

the cured piece with a coping saw or band saw.

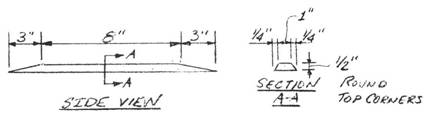

.....Take the cured 10"x16" piece to your post office, or any accurate scale, and ask them to weigh it for you. Your laminate should weigh between lO 1/2 and 12 1/2 ounces. A 10 1/2 ounce layup is about as light as can be done without voids (white areas). A 12 1/2 ounce layup has too much resin, and if you make all of the 1ayups in the airplane this wet, your Q2 may be as much as 50 pounds over weight. An 11 ounce layup is just about perfect. Save this piece; it will be useful to check future 1ayups against. CONFIDENCE LAYUP .....The second practice layup is one intended to give you confidence in the strength of your work. This layup is a sample of composite sandwich structure and is typical of the load carrying structures in your Q2. When this layup is finished, and completely cured, you will subject it to a simple load test, and thus demon¬strate the strength of your workmanship. .....First, tape a piece of waxed paper about 30 inches long to the top of your work table. Shape a piece of green foam as shown.

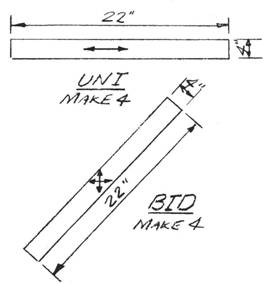

.....Go to your glass cutting area and cut the glass plies shown.

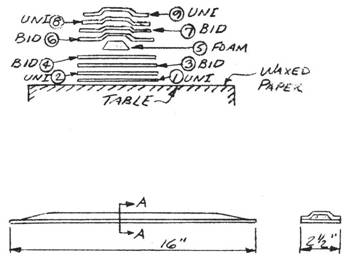

.....Lay up two plies of UNI, two plies of BID, paint the foam with micro slurry, and press it in the center. Then lay up the other BID and UNI plies. Be careful to work a11.air bubbles out of the corners. The best way is to stipple with the brush. The glass is oversized so that it can be trimmed to exact dimensions later. Trim to the dimensions shown after curing 24 hours, using a coping saw or band saw. Allow the piece to cure for four days at room temperature before the load test.

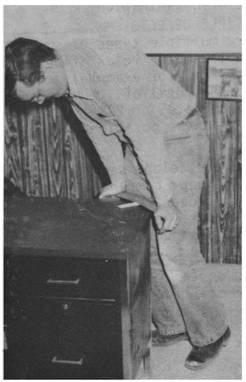

.....Now for the test: lay a broom handle or piece of tubing on the work bench and try to break the sample by putting all of your weight on the ends. A 200 pounder will stress the sample more than any part of your airplane is stressed at 10 g's.

|

||||

PAGE

3-20 |

||||