Q-talk 29 - LETTERS

- Details

- Category: Q-Talk Articles

- Published: Saturday, 31 August 1991 07:11

- Written by Jim Masal

- Hits: 2751

Jim:

My most recent efforts have involved the alignment of my wheel pants to the canard of my Q-200. Rather than use the normal method of optically aligning the pilot holes, I used a small helium-neon laser. As documented in the enclosed photographs, the laser unit is mounted cantilever fashion to the outboard side of a wheel pant. I used three smaller diameters of brass tubing nested inside a 1/4 inch O.D., 12 inch long, section of brass tubing as a beam channel. I placed a channel through the pilot holes of each of the wheel pants. The laser was mounted to the outboard side of the right wheel pant and a black construction paper target was located outboard of the left pant.

The canard setup was as follows: the canard was jigged and hard Bondoed at BL15 and loose mounted with BL31.9 templates. The jib table was leveled to less than .1 degree spanwise. Working temperature varied from about 76 to 85 degrees F.

After fit checking the wheel pants, each was individually adjusted until the .48mm beam was passing through both beam channels. Miss alignment was easily displayed by distortions in the circular red spot of light on the black target. It should also be mentioned that there is an approximate .25-inch diameter red circle, which propagates about the true beam diameter. Though about 5 hours was spent attempting alignment, I never could achieve perfection according to the laser, but it was close.

Lessons learned: The pants in this case were floxed into position. During the first attempt the right pant started to move as the flox reached cure. The laser indicated that there was outboard movement of the pant as the beam moved out of the left hand pant channel and approximately 1.5 inches high of the channel. The pant had been secured per plans using plywood supports held by Bondo. The suspect pant was removed and prepared for another attempt on the second day. The left pant was realigned and floxed with two additional supports. On this occasion the laser was run continuously for truth reference. At the four hour and six hour points the pant moved. I could not correlate any of the observed motions as they were in random directions. The pant was realigned in place by attaching 2.5 lb weights via bungee cords.

This experiment verified some speculation, which I had about movement of components during cure and suggests that alignments be verified all through the construction process. There is also a suggestion that more elaborate jigging schemes are required to approach and preserve precisions. The beam was also used in this case to verify that the pilot hole line is 90 degrees to the BL00 line. This activity did not save any time or money. It was done for confidence. With some thought, however, this method can allow fast and accurate wheel pant placement with no guess work. The addition of smaller diameter tubing into the nested channels would tighten the accuracy up a lot. Eye balls and string are probably just fine for this project though.

Laser details: size 2.5 x 2 x 7.25 inches, 1.125 lbs wt., Power .5mW, Beam dia. .48mm @ 1/e, divergence 1.7 mrad, pointing stability <.10 mrad cold start ;<.01 mrad warm. Follow manufacturer's cautions and do not look into beam. The light is intense, monochromatic, and coherent.

Brian M. Martinez, (805) 943-5379

I don't think the pics Brian sent will show the laser beam very well in black and white so I didn't include it. It sure is a neat trick, though, for all you working on the aforementioned "warts". - ED.

Dear Jim

I had hoped to have my Quickie up and flying with its new ROTAX 503 (dual ignition) engine and a new drum brake system; but my partner Harry Buskey ups and moves to Texas, leaving me to complete the conversion. He has, however, agreed to come back to NC and do the initial test flights.

As reported to the gang at Oshkosh (1990), converting from the original tire scrubbers to go-cart drum brakes has been completed, but not tested. This required sawing the large wheelpants right down the middle, adding 1 1/2 inch foam spacer, extending the box beam, moving the brake cable pulley from the inboard side of the wheelpants to the outboard side, reglassing and painting. The brake assembly/wheel (including everything that goes on the axle between the two wheelpant sides) was a masterpiece of Harry Buskey and there just might be .001 inch lateral play overall. He even justified the purchase of a 12-inch floor mounted lathe with all sorts of accessories just to fabricate Quickie parts. The precision he used to get out of his little Unimat lathe was an amazing feat, but now he tosses 0.0005 to 0.001 inch tolerances around even when cutting an aluminum spacer that the average homebuilder would do with a hacksaw. Not only did he leave before we finished, he even took his lathe with him.

The ROTAX engine conversion is coming along nicely. Lost a lot of time modifying the cowling. Believe I could have started from scratch and saved time. I confess, the cowl we purchased was a nice cowl; it's just that we wanted to change this, then that, to the point where the original builder may not recognize it. Basically, we used Jinx and Brock's plans with very few changes. The cowl is complete except for final painting. Have completed 2-hour run-in on the engine. After nearly 400 hours on the Onan, the Rotax gives the feel of having solid propellant boosters strapped to the sides of the Quickie. Am down to the final installation of hardware - thermocouples, choke and throttle cabling, wiring, fuel lines, mounting bolts, cotter pins, etc... under the cowling. A lot of the cockpit work is completed, yet a lot remains - radio installation, rudder pedals, cables, mounting bolts, all control rods, wiring, etc...

Externally, I have a loose center pin in one of the elevators to be repaired - this could be a dog to fix. Also, I plan to fabricate a fin or skate (with about 1 sq ft surface area, as viewed from the side), which will be glassed on the underside just forward of the tailwheel. This will serve to improve stabilization as well as contain the added weights needed to put the planes weight and balance in the proper envelop.

I am now looking to next spring for start of test flights. Had hoped to be doing it this fall, but some unexpected events changed my plans. All mods are being recorded on video which I plan to make available to anyone interested in a "This is how I did it", not a "How you should do it". More on this in future Q-TALKS.

Ves Fulp, Greensboro, NC

Dear Jim:

I'm enclosing a couple of photos of my Q2. I've been flying it for two years now and have about 50 hours and 90 landings in it. The takeoffs and landings still take my full attention. Once it's in the air, however, there are no surprises - responsive and fun to fly. I have the Revmaster engine and except for a persistent oil leak from the area of the rear main bearing I have had no problems. I have changed the rear main bearing seal, but it did not stop the leak. If anyone has an idea, I'd appreciate hearing it. I also experienced a high fuel burn, which was corrected by replacing the needle valve in the Revflow carb. Revmaster sent me a new one free of change.

You may remember I got in touch with you to ask if you knew where to obtain replacement tires for the original 4.00x5 Cheng Shins. I searched high and low calling commercial dealers, Custom Composites, Aircraft Spruce, Wicks, etc. etc. to no avail. I was finally able to get a set from Dave Fulper who advertised in the July/August Q-TALK. I did later find one possible lead from MATCO Mfg (801) 486-7574 who lists a nosewheel that may be the correct size. My tire wear is caused by an alignment problem; if you know of a good way to realign after the fact, I'd appreciate hearing about that also.

If anyone would like a flight, I'd be glad to take him/her up.

Manny Lewis, Scotia, NY (518) 399-8614

Dear Jim,

I have bought Jinx Hawks Rotax 503 and am tearing off my Cuyuna with great anticipation. The Cuyuna was (looking back) a very poor choice for power and I am only sorry that I wasted six months and $?. The upside to that is that I will have the chance to reclaim lost money after I make my first flight over the city and prove some people wrong!

Robert Bounds and Jinx have been in contact several times the last few months and they have really helped with suggestions and motivation. It's really great to have guys around that will take the time to do this. I'm just really sorry that Jinx lost his Quickie.

The good news is that the little bit that I had 92GW in the air she sure did fly nice. But because of overheating and whatever else never made a complete pattern.

Having my baby back in the shop has motivated me to make several changes while waiting for the new engine. I installed brake pads using mud flap material (the stuff with the cords), they seem to work great but had to be super thin to fit. I cut the fuel tank open for (hopefully) the last time and used Sloshing Sealer; I found the tank very difficult to tumble as it is hooked to the plane so I painted the stuff on. I am also switching to 100LL. This had better solve the leak or else I will have to take some drastic measures (cut it out and start over). My trim system was far from adequate so I have installed a home brew thingamajig that looks similar to a throttle (lever type) with notches for a locking feature, will see if it's any better. Also have stuck some cabin heat in, will I be the first Quickie jock to fly in forty below weather? (Don't think you'll even catch me outside in that stuff!!)

I'm really anxious to see some of the other Quickies out there so drop me a line and a picture!

Jon Finley, 2217 Choteau St., Helena, MT 59601

(406) 449-8872

Dear Jim,

Enthusiasm for our TriQ-200 reached an all time low in 1990, with no work being accomplished the entire year. In fact, I didn't renew our QBA newsletter subscription ... even though our soft hearted editor sent me a reminder postcard!

Enthusiasm returned in '91, and work has restarted. Our tail is now white, cabled and ready to fly. We will now concentrate on painting forward of the split line, and on panel and engine wiring and plumbing when it gets to cold to paint.

As such I am sending my 91 dues and hope that dear good person Jim (flattery will get you anywhere, huh?) will send me the issues I have missed.

We did get to attend Oshkosh this year for our first time. Bigger than you can imagine. Saw many Q-birds and talked to many pilots. Went to the tent forum on Friday night, and the Wine and Cheese on Sunday. Very valuable trip, I highly recommend it for anyone currently building; allow two days or more at Whitman.

In order to redeem myself with Masal and QBA, I am volunteering to process the return cards for a propeller survey. I will work up a postcard that will be stapled into the QBA. The card will have fill in the blanks for Aircraft, Engine, Propeller pitch, diameter and make, and some resulting performance(s) at various altitudes. These will have my return address on them; I will summarize the data and present results in a future QBA. If you have a particular piece of data you wish to see collected, call (817) 467-0373 and leave a message; a machine will answer 24-hours.

That's all for now, I am going to go sand and paint, sand and paint ...

Danal Estes, Patricia J. Wright

1400 Seely St., Arlington, TX 76018

(817) 467-0373

Here is my idea for the card:

| [] Quickie | [] Q2 | [] Q200 | [] TriQ2 | [] TriQ200 |

| Engine: ____________ | Weight Empty: __________ | Gross: ___________ | ||

| Hours Airframe _______ | Engine: ____________ | SMOH ________ | STOH _____ | |

Fuel: | [] 80 | [] 100LL | [] Mogas: ______________ | |

| Propeller Pitch: __________ | Diameter: ___________ | |||

| Manufacturer: ____________________________________ | ||||

| Den Alt | Weight | CAS MPH | RPM | GPH |

| __________ | __________ | _________ | __________ | _________ |

| __________ | __________ | _________ | __________ | _________ |

| __________ | __________ | _________ | __________ | _________ |

| __________ | __________ | _________ | __________ | _________ |

| __________ | __________ | _________ | __________ | _________ |

Anybody who feels like getting a jump on this project is welcome to fill this out now and shoot it off to Danal and Patricia right now. - ED.

September 22, 1991

Dear Jim,

I thought you might be interested in another progress report. My Q-200 now has 530 hours and we're still flying. I was never very happy with the brake mount system, so I converted to the Bob LaRue system. The only change was to make the mounting bolts out of steel, instead of aluminum, and it is one continuous bolt, instead of two bolts butted head to head.

My brakes always chattered badly, never were even, and they'd keep pulling back and forth. Braking was never much fun. Now they are even, quiet and smooth.

At the same time I did the brake work, I adjusted the camber. When you build the canard on your workbench, the plans tell how to set your camber and toe out. (Zero camber and toe out set by aligning with the opposite axle and aiming 2" forward.) The problem comes when you place a load of 550+ lbs on the canard. The canard bends and the wheel pants naturally splay outward, so all of your careful alignment is shot. To make things worse, as your aircraft ages, (and sits in the hot sun) the sway in the canard gets even worse. As a result of this great increase in camber, I was getting very bad tire wear patterns and the plane kept getting more and more skittish on the runway.

When I started assessing how far the condition had progressed, I found if I sighted through one axle, the alignment point focused a full 10" below the opposite axle! The toe out had not changed appreciably, but the camber was terrible.

I corrected the problem by plugging the inside axle hole, making appropriate glass repairs, and redrilling a new hole 3/16" higher.

I would suggest that builders consider moving this inside axle hole during the construction process.

By changing the brakes and fixing the camber problem, my rollouts are straighter, smoother, and I should get a lot more mileage out of my tires and brakes.

I also had a hair-raising incident just like Art Jewett. My passenger and I had just lifted off runway 06 (3000') and gotten to about 300' when the engine suddenly lost power and we started descending. I declared Mayday and brought the plane around for a 270 degree left turn to attempt landing on the intersecting runway 18.

The power seemed to come back, up and down but never got very good. I could smell fuel real bad and could see a white fog of fuel at the right side of the canopy. My passenger (another Q-200 builder) was petrified.

I wanted to land on runway 18 (5000') but over the numbers I was a hundred feet too high and about 40 mph too fast. I knew that I would wind up touching down on the last third of the runway and would run off the end if I tried. The only thing left was to do a go around. I pushed the throttle in and sputtered around the pattern again, probably never getting any higher than 300', and safely got it down.

So what happened? Well, I always felt the Quickie/Q-2/Q-200 fuel system was rinky-dink and it is. Do you know the plastic bottle that you use for a fuel filler cap? Well, over 4 years and many fueling operations, the plastic threads had become brittle and one day they cracked and split off. Remember, the fuel system is pressurized by a ram air vent, but when the fuel cap seal is ruined the low pressure outside of the fuselage actually sucks fuel and air out of the system, resulting in inhibited fuel flow to the engine.

For a temporary fix, I was able to get a rubber automotive freeze plug, which is tightened and exactly fits the 1 3/4" PVC pipe.

The QAC fuel system of soft aluminum tubing, and plastic tubes and caps is just asking for inevitable trouble. Consider switching to standard aircraft plumbing.

Remember I wrote to you for Bob LaRue's address and you said your computer dumped it? Well, I got the N number of his Q-200 from a previous Q-TALK and wrote to the FAA's Department of Aircraft Registration (the same address on your aircraft registration/application certificate). To my surprise I received a reply in about one week! This is a tip for other builders. If you want to contact an aircraft owner and don't know who they are, just send the FAA the N number and you'll have the name and address in short order. The service is free, too.

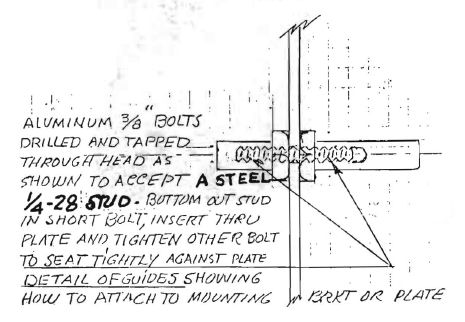

Anyway, if you want it, Jim, Bob LaRue's address is: 561 Via Del Monte, Palos Verdes Estates, CA 90274. I wrote to Bob and asked him about the drawings of his brake parts he supplied to you about a year ago. It seemed to me that there was a weak point in his system and I wanted to question him further. The entire torque load of the aircraft was taken up by just two 10-32 studs. He replied that indeed there was an error in the drawings, that the 10-32 studs should actually have been depicted as a 1/4-28 steel stud. He also requested that I forward a corrected version of his drawing to you, so here is his plan.

I've sent out quite a few builders checklists now, ($2.00 and a SASE to: Sam Hoskins, 400 C Beadle Dr., Carbondale, IL 62901) and I thought you might like a word or two on how to best use it (or any maintenance checklist for that matter). Any checklist should attempt to cover all items (I've tried to do that) but in addition, a logical method is needed to precede with the inspection goes hand-in-had with the checklist itself. After each item of the checklist you should have room for 2 columns to put your initials (or date), one for the first inspection and the second for item complete. I recommend that you proceed in the following manner:

Proceed through the checklist, generally inspecting only. When you have thoroughly inspected the component or part listed, put your initials (or date) in the first space next to the item. If the inspected item is perfect and ready to fly you may put your initials in the second column. Otherwise, if you find a defect, make a complete note on a separate squawk sheet and then proceed to the next item on the list. After you have finished a general area (wing, canard, engine, fuselage) go back and correct the discrepancies. Using this method will allow you to keep track of what needs to be looked at, what remains to be inspected, what needs to be fixed, and what is airworthy. Also, you will make the most efficient use of your time when correcting discrepancies. Of course, some maintenance items will need to be corrected at the exact same time they are inspected, but the general rule is to wait until inspections are done.

If you are getting ready to fly for the first time, have someone else do the inspecting. He may see some of your work in a different light.

Sam Hoskins, 400 C Beadle Dr., Carbondale, IL 62901

(618) 549-3302

You can order a PDF or printed copy of Q-talk #29 by using the Q-talk Back Issue Order Page.