QuickTalk 21 - Q-2 HINTS

- Details

- Category: Q-Talk Articles

- Published: Tuesday, 30 April 1985 07:11

- Written by Jim Masal

- Hits: 2558

I'll have to go along with Fred Wemmering about Q-2 builders having more guts than brains. I really like my Q-2's flying qualities, but landing and ground handling leave a lot to be desired. For my money, the Tri-Q is the only way the Q-2 is ever going to be a good airplane.

I've enjoyed my Q-2, N707V, and have 65 hrs to date with no damage so far. I'm real pleased with the way the airplane flies. I have about 7,500 hrs pilot time in fighters and different aircraft, so I know a little bit about how an airplane should fly. My biggest problem has been with the Revmaster engine - getting the POSA/carb needle adjusted right and finding the correct place to pick up the CHT (gauge was reading too hot).

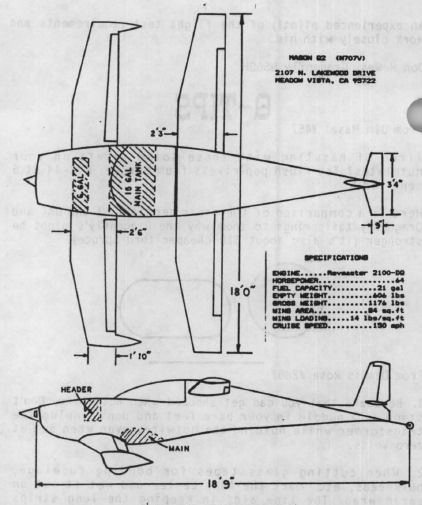

I made many modifications to my kit: 20 square ft. more wing area (from 64 to 84 sq. ft. - longer chord and 18 in. to the length to make 18 ft. total); landing brake (belly board); 9 in. more length to each elevator and 5 ft. long ailerons with a center hinge; my own design reflexor to help landings; aileron trim system; an uncut canopy which is 2.5 in. higher and squarer on the sides (lot more headroom and visibility) and allows a handy baggage area behind the canopy; full IFR panel; full flying horizontal tail hooked to the elevators and control stick but can be trimmed independently; different and larger vertical fin; 100% balanced rudder, horizontal tail, ailerons and elevators; retractable step on the left side to help people not too agile.

The training wheel that shows up in the QUICKTALK #20 photo was just used for the first few flights because the tail is light and I thought the plane might want to nose up on landing when brakes were applied. I haven't had any trouble along that line. The brakes are hydraulic with a parking brake lock.

While I had the airplane home during the winter, I made a lot of small improvements: 5 degrees more up on the horizontal tail, new engine baffling, gas line from header tank to engine with a gascolator and drain cock in line, "bird strainers" on the canard elevators like the Q-200 (they seem to make the plane fly better), and I painted the top of the canard flat MATT to make the canard lift better in light rain.

N707V indicates 155 mph at 3,000 ft. and 2950 rpm with 2 on board. In a stall the airplane just mushes down at 700 fpm in landing attitude, straight ahead with stick full back at 65 to 70 mph.

Ira E Mason #2077 N707V, Meadow Vista, CA

ED NOTE: Fortunately Ira is well pleased with the performance of his ship. Not everyone gets away scot free when deviating from the plans (e.g. there was a San Diego Q-2 fatality 2 yrs. ago attributed to faulty hookup of an oversized horizontal tail). It would be interesting if we could know the direction and magnitude of performance benefit attributable to EACH modification but this can only be done one mod at a time with careful test flights and measurement on each mod. Nevertheless, isn't it great that the FEDS let us "experiment" to our heart's content?

I still keep running into things, which simply do no fit as per the plans. My main fuel tank is right on the mark for forward placement, but the control supports touch the tank and had to be cut to fit and clear for the new canard fitting. More work. Now I find that with the sweep back the elevator control tubes do not clear the tank as they exit the fuselage - more cutting and filling and patching to make a good clearance and a gas tight tank. What hurts is that I had heat tempered the tank before assembly and now there is an untempered spot to be carefully heated. BUILDERS BEWARE -- MOVE THAT TANK BACK AT LEAST A HALF AN INCH.

Harvey Nack #2046, Glen Ellyn, IL

From John Beck #2238

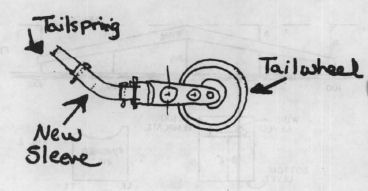

One comment about the Q-2 tailwheel mod (QUICKTALK #12, pg. 6): it seems to be necessary for ground stability to have the pivot point vertical but instead of all that cutting and welding on those pretty parts, how about a sleeve fitted over the tailspring that fits inside the pivot? The sleeve would be bent to the proper angle. Perhaps QAC should offer these sleeves bent in several different angles and the builder could determine the angle needed after the plane is constructed. Also, what about heating the end of the tailspring and just bending it to the proper angle?

I was intrigued with Bob Falkiner's reflexer option (QUICKTALK #17), especially since I had QAC's kit on hand. I did buy the phenolic 3/8" and with the extra 1/8" aluminum on hand, made Bob's unit. The parts weight exclusive of cable and cable bracket was 7 oz for Bob's vs. 10 oz for QAC's. The bad news is that Bob's unit will allow the QCSA3 to flap or move up and down at will if the cable tube breaks whereas QAC's unit will more likely only leave the QCSA3 at the position it was in at the time of wire breakage. I would hate to lose control due to ailerons flapping up and down. On QAC's unit, I have drilled out QCSAR7, cut a short section of tube off the end for a spacer and placed QCSAR7 on reversed so that the lever arm is much closer to the FS 94 bulkhead, making travel limit stops and control cable mounts more feasible. Decreasing total tube length of QCSAR7 and QCSAR6 may remove 1+ oz of weight as well. Some combination of these 2 designs may be the best of both worlds.

Henry Hurd #2533, Belleville, IL

From John Derr #2562

An easy way to make perfect "sparrow strainers", the elevator trim surfaces for the LS(1) canard, or to form balsa for other purposes, is to pretend you're hot wiring foam. Make two metal templates for the airfoil cross section just a little oversize, say, to the outside edge of the line on the paper template. Square up a block of balsa to the proper dimensions, nail the templates to the ends, and put it on a belt sander. Use a coarse belt to take it down to a point where you just hear the sandpaper hitting the template. Next, change to a medium grit belt and finish the surfaces. By the time you're done, you will have sanded off the width of the ink line on the template and the surface will be ready to glass.

You can order a PDF or printed copy of QuickTalk #21 by using the Q-talk Back Issue Order Page.