QuickTalk 18 - LETTERS

- Details

- Category: Q-Talk Articles

- Published: Wednesday, 31 October 1984 06:11

- Written by Jim Masal

- Hits: 2555

I write this for anyone who may be doing what I did for two years -- sitting back, reading the letters in the newsletter and trying to decide: 1. Do I really want to get involved in this big of a project? 2. Do I really want this to be a Q-2/200?

There were many times that I just about chucked the whole idea based on the "letters" section of the QBA newsletter. Backorder and other problems with QAC, and after that, trouble with ground handling qualities (dangerous!?!) of the Q-2 concerned me.

Well, I have had my kit 1A for about a month now so let me relay to you my actual experience and give some advice for people thinking about "going for it". First and foremost, get yourself a good dealer - one who has built and flown the aircraft. It is an immense help. If you are a first time builder and especially working with composites, Burt Rutan's tape on construction methods is invaluable beyond words. I feel it will pay for itself many times over with time and weight savings. A picture is worth a thousand words.

As far as the horror stories about QAC - I have no doubt that at one time they were not without merit. A year and a half ago I ordered a T-shirt from them and they messed up an order as simple as that. However we have all read about improvements they were trying to make and I believe they have done it to a great extent. The kit arrived about when the dealer said it would. It was missing some parts, however this was expected since a letter from QAC earlier advised me of the possibility. I simply fired off a letter listing the missing parts and I had them within 10 days. Connie Parker at QAC was especially helpful.

Assuming the rest of construction goes in a similar fashion, that only leaves flying the hot little devil. I have talked with a number of people who have flown their projects, including Scott Swing who probably has one of the nicest Q-2's going, and even though I'm a low time pilot, I believe that if you don't press beyond your current ability and take it slow and one step at a time that my Q-200 will prove to be the craft I expect and can be handled - with respect.

...after a month...I have had no trouble with the plans, construction (with the help from RAF's tape), or the dreaded epoxy. This was a real worry point for me as I have seen the ads for fellows selling their projects due to the allergic reactions. However, I am down to using Ply-9 gel with no adverse reactions.

Conclusion - up to now, 90% of the letters in the newsletter have been from people who have had trouble and were letting it be known. I do thank these people for giving me something to watch out for. However, based on my experiences up to now, I believe there are many more out there with no troubles to speak of with their planes and I would hate to see someone who would like to try one of these kits discouraged without hearing a little from the other side.

Ted W. Fox #2855, Mansfield, OH

Ed. note: As I typed the above my wife wondered why I had such a Cheshire cat grin. No comment. One of QUICKTALK'S goals is to help a builder in this emotional market make an informed choice about Quickies and Q-2's. We hope Ted's experience with QAC are voiced loudly and clearly by hundreds of builders nationwide, but 90% is not a statistic this gray haired ol' editor will dismiss! Keep us posted, Ted.

Some comments to those who are unhappy with the Q-2.

I purchased my kit complete from a dealer in Oct. '81. He offered no suggestions as to what options were absolutely necessary. For example: when I received the engine I was irked to note that it would be impossible to change the oil without first removing the oil cooler. The quick drain oil sump should not be an option, it should be an original component part.

The POSA carburetor had a fuel inlet fitting that was not compatible with the fuel system outlined in the plans book.

The 10 gallon kits of Safe-T-Poxy proved not to be enough to complete the kit, yet no additional kits were provided. Of course the "cover your tracks" gratuitous offer of additional BID cloth was the cheapest action taken by Quickie Corp.

The recommended use of Dupont 70S primer is really a pain. It's extremely dirty and sands off with the meekest effort of 600 grit wet sanding. I think they overplay the UV barrier pitch. Dragonfly uses 100S, it's gray, and its also called a UV barrier.

There are enough stories out now to prove the original Q-2 GU airfoil is an accident waiting to happen. Pity we who are stuck with it and cannot afford the new canard for the Q-200.

As for Revmaster, I didn't know until Sept. '84 (3 yrs after receiving my 2100DQ engine) that the supplied direct drive starter will not turn over the engine using the 12 V 18 amp. hr. battery recommended in the plans book. Even the geared starter is an option; it should have been original equipment. Revmaster took us to the cleaners!!!

The cheap throttle cable provided in the kit is too long and doesn't operate smoothly. Result: buy another one of greater quality and of proper length. Just another $40 rip off as a result of Quickie Corp.'s effort to either pad the profit margin or just plain p.p. quality control through the whole ball of wax.

In summary, I hope I can at least start taxi tests within the next two months. In the meantime, I'm waiting for a geared starter ($180 with exchange), a new throttle (4-6 weeks wait) and a correct fuel fitting. My recommendation to anyone considering a homebuilt is to stay away from anything having to do with a Q-2.

Fred Wemmering, Fayetteville, NC

Gentlemen, I am so totally frustrated after 4 years and 1200 hrs building and $9000 Canadian. I have a beautifully built Quickie with a piece of crap for power (22.5 hp Onan). This assessment is based on my 2 engine failures and safe, no accident landings both times, but only by the grace of God. I have 2000 hrs total flying, most of them flying floats in the mountains commercially, and I have had many learning experiences the hard way, but never an engine failure. I repeat, never. And then I have 2 in my last 5 hrs flying my Quickie.

B.S. fellas, that motor ain't intended to fly. The Onan dealer in Vancouver, a mechanic who has tried and tried says impossible - it simply won't handle elevation changes.

I know there are many who are doing it - somehow - and I guess I admire the pilot's nerve or determination etc., but frankly, I've had enough. The airframe flies so perfectly (ask Martin Olson of Golden, B.C. who did first flight) but all the joy is invalidated as you sit and wait for silence. The plane is for sale cheap.

I still have a glimmer of hope for a new engine conversion, but Stubbs is out of business so no Koenig. John Hicks of FL mentioned the Eipper Lotus as an alternative at 50 hp. Come on John, stay in touch and let us know what you're doing. Any other alternatives would be appreciated too.

I can't believe there are that many suicidal Onan powered Quickie pilots out there. Come on, what are you using for power? I guess misery loves company, but before you hurt yourself, you might get an opinion from the boys who build the Onan. Has QBA listened to their opinion?

Bob Shellon, Naskusp, B.C., Canada

Ed. note: We don't need to talk to Onan; we get enough letters from you guys. Besides what can they do for us - design a new engine? Refund our money? We are stuck with what we bought. We are left with either beseeching QAC for help or helping ourselves, which is what QUICKTALK is all about.

I have a question I wonder if anyone has come across before. My fuselage was glassed two years ago. Prior to covering and storing it I went over it carefully with a flashlight checking for epoxy lean areas, delaminations etc. Any imperfections were circled with a black marker. Now that I have new life in my veins, I have begun work on my fuselage again. Upon inspection I notice 3 or 4 areas where the fibers were white. The largest is approx. a half-inch square so I don't think I would have missed it on the first inspection. These are soft to the touch...what could have happened?

Joe Hantz #535, Hackberry, LA

Ed. note: I dunno. A paint remover will soften fiberglass. Anyone else seen this?

I am, as it seems all the QBA members are, slogging along in my quest for an ultimately flyable Q-200. And...wondering if I'll ever finish.

Part of the reason for my slow progress is that I am finishing graduate school at the S.I. Newhouse School of Public Communication at Syracuse University and am beginning my thesis for my Masters degree. The topic, what else? The homebuilder of aircraft.

Jim...would you please mention in the next newsletter that I'll likely be contacting most of our membership seeking their help in identifying, quantifying, defining, and just generally attempting to obtain some empirical data on who and what we are and what our market potential is? This sort of research has never, to my knowledge been done...It might actually be of some value to us all some day.

Lynn A. Faulkner #2794, Manlius, NY

Delighted, Lynn...just so that you share some of the preliminary results with us. We oughta know who we are too! EDITOR.

I have recently built, flown and wrecked my Q-2. The enclosed letters describe events leading up to damaging the airplane, QAC's response and subsequent actions. Actually, and contrary to Sheehan's comments about wanting to be of help during the test and taxi phase (ref. QUICKTALK #15), QAC has been of no help.

After ground looping my aircraft without damage during taxi tests, I decided to visit QAC, get a ride, and discuss what I consider to be a ground handling problem. During that visit, I was mostly ignored, and barely got a 10-minute ride in Scott Swing's airplane. Questions were not answered. Erick Shilling is the one who told me to stop doing high speed taxi tests, and that landing rollout was the most critical area in the airplane's operating envelope.

I started my airplane (SN 2622) in Jan. '82 and brought it out to the airport in March '84. The airplane took 1987 hours to first flight, which occurred on May 17, 1984. I damaged the airplane on my 19th flight, 24 June 1984. The damage occurred as a result of the airplane gently turning into a 10 mph crosswind and I could do nothing to prevent it. During the 19 flights, I managed to get 33.5 hours on the airplane, changed to the new 75 hp heads and made numerous mods in trying to get the oil temperature to run cooler.

The airplane weighed in at 575 lbs, and is equipped with oil filter, side drain, and geared electric starter. The instrument panel is heavy--it is well equipped with Nav/Com and transponder. It holds a total of 26 gallons: 7 in the header and 19 in the main tank.

On my tach I have never seen over 2600 rpm static or 2800 rpm in flight (unless in a dive) with either set of heads. Indicated airspeed at 10K runs about 140 mph on my gauge with the cowl flaps open (oil temp). Because of the hot weather and oil temp, I have not run the airplane at full power at low altitude. The airplane is super in the air; it responds well, trims out nicely, and runs well in rough air. Stall and pitch bucking are exactly as described by QAC.

Flying into rain is first felt, not seen. It feels like someone is trying to pull the stick out of your hand, and you feel this before you see rain on the windscreen. The elevator moves from about 1/2 to 3/4 inches trailing edge up (in cruise) to about the same amount down, to trim out in light rain. You lose at least 10 mph on the gauge. I do not have a T-tail or reflexer on my airplane.

On landing, I feel most comfortable on a fairly flat final using 90 mph and a little power. As a result of picking up bugs, I added an elevator position check on base leg and final as part of a normal crosscheck to ensure that the elevator is in the normal position I've become used to seeing -- about zero degrees (faired). So far, the light bug buildups which I've encountered have not caused any problems.

At this time, I have not decided what to do with the airplane. I have it back at home but hesitate to repair it and, again, end up with bad ground handling characteristics...I could sure use some help.

Don Ismari, Las Vegas, NV

ED. note: At Oshkosh, Sheehan told me that he had written to Don regarding a possible fix. His letter follows:

Dear Don,

Thanks for sending me your notes and comments. Sorry for the problems that you've been having.

You are correct in assuming that we are extremely busy in preparation for Oshkosh. However, I have quickly glanced over what you've sent us and have the following initial comments.

Quickie Aircraft Corp has indeed addressed the ground handling problems that some builders have experienced. I have enclosed a copy of Newsletter #20. Please look under Q-2 Builder Tips.

In reference to your 9 July note, if your axles are indeed at FS40, that might well be the source of most of your trouble. You're not the only one who has wound up with axles too far to the rear. If you carefully read the Builder Tips in NL #20 you will note that we suggest moving the axle forward by 3/4". Obviously in your case, since you are 9/10" to the rear, you could move yours forward 1.65" from where they are now. No call or correspondence with QAC would have been necessary for this change. We would recommend that you also add toe out at the same time as described in NL#20. By accomplishing both of these actions, you will definitely improve ground handling.

You may also have too high ground angle of attack. What happens when you do is that the rear wind continues to fly after the canard signs off on roll out. This obviously reduces the amount of weight on the tail wheel, which in your case would already be a little light due to the main axles being aft of where they should be. One thing you can do in this case is install smaller tires such as Goodyear 350-410-5 on your wheels which will drop your main axles about 3/4". Alternatively, when you move your main axle forward, you might be able to move them up a little also. Again, either of these steps will improve ground handling.

As to your needed repairs. Without the parts at hand to look at, or photographs in lieu of that, it's difficult for us to recommend a repair procedure. Please send us detailed photos and drawings of the damaged area.

Please get in touch with me after Oshkosh.

Best regards,

Quickie Aircraft Corp

Gene Sheehan, President

OSHKOSH CAMPAIGN

by Robert Herd, #478

It was a question that had bothered me for the last couple of years. Of the 1200+ Quickie and Q2 kits that have been sold since 1978, why do only a small handful ever show up at Oshkosh every year?

I couldn't stand it any longer and finally asked Gene Sheehan the question during the Quickie forum at Oshkosh. His immediate response was that "the Quickie really isn't a good cross-country airplane" and perhaps some pilots may also be intimidated by the Oshkosh control pattern. (Hrumph! This seemed a little unusual coming from a man whose sales brochures tout "...any aircraft which is not flown cross-country to Oshkosh should not be offered for sale to the general public.") Taking a different avenue on the flight line, I talked with pilots, asking why they did not bring their completed craft to Wisconsin. Quite a few mentioned the hassles involved as well as a question of long-distance mechanical reliability.

Well, frankly, I can't accept any of the above reasons for such poor attendance by our ranks anymore. Piper Cubs and even ultralights are pretty poor cross-country aircraft also, but you see a hell of a lot of them at Oshkosh. And their pilots didn't appear unable to cope with the rigors of the traffic procedures, either. If it's a problem of poor aircraft performance, then it's time we quit grousing and got our individual problems fixed. (I know that Doug Swanningson seems able to make it from Florida every year like clockwork. Maybe we should ask HIM what he is doing right.)

I feel very strongly about this issue simply because the time and money many of us have invested in our kits should not be wasted. The Oshkosh Convention is a prime indicator of how well an airplane is accepted in the marketplace and its future desirability. In other words, if no one sees our planes at fly-ins and such, there is less chance that potential buyers will be enticed toward a Quickie or Q2 (and thus its resale value deteriorates). So much for economics...

There is one item that could be done which might be a lot of fun and provide some peace of mind for the distant traveler. That is to have a GET 'EM TO OSHKOSH campaign to beg, cajole or arm-twist everyone into attending. We could feature formation flight routes across the country, a central flocking point and perhaps an en masse assault of Whitman Field. There is, indeed, safety in numbers as well as a chance to compare side-by-side performance data.

Nothing would be more pleasing than to see dozens of Quickies, Q2's and Q-200's descend upon Wisconsin next year. If you would be interested in such a group activity, let me know. I'll be especially interested in hearing from those of you who plan to finish construction in the next few months. Write to: GET 'EM TO OSHKOSH, c/o Robert E. Herd, P.O. Box 8604, Ft. Worth, TX 76124-0604. NOW is the time for us to start making arrangements. I'll do all I can to help every individual make it there in their own project. Will be looking forward to hearing from everyone and your suggestions for our campaign.

After reading J.P. Stroud's letter in Issue #16 and the ED. note following it, I thought this information might shed some light on what appears to be the 2 Kawasaki powered "Quickie Mystery Ships" that were at Sun 'n Fun.

N4WH was trailered to Sun 'n Fun by Advanced Engine Design of Flint, MI and flew a total of 3.5 hrs of demo flights with AED's engine (Mon. thru Thurs.), morning and evening except Tues. evening. Jack Binswanger did the flying and says the engine, based on the Kawasaki 440A, gives the Quickie much added and needed performance. Climb rate observed from the ground and confirmed by Jack after flying appears to be 8 to 900 fpm. We had no VSI and Jack was too busy to time it to 1000 ft AGL that was his traffic pattern altitude (where he throttled back each time because he felt it would keep on going up all day). The lovely weather was 85 degrees most of the time and N4WH would get off in about 400'. We were using a 44D x 52P Prince prop with "P" tips and are very happy with the whole combination "firewall forward".

Comfortable cruise speed is about 135 mph and top is between 145 and 150. We're not finished fine tuning yet so these are approximate.

I built N4WH exactly as the plans and it flew well with 18 hp but after I made the 22 hp conversion I never really felt comfortable with it, so have only 3 hrs in it. Jack has about 50 hrs with the Onan and about 14 with AED's 38 hp. With the added hp, I'm anxious to try it again. Most of our flying is out of 2600' strips usually with trees at both ends so "getting away from the dirt" is made easier with a good engine/prop combination. I guess none of us would need that added expense if we flew out of 7000' or more with open approaches (like where the Quickie was born).

The engine is very smooth and very quiet (that's probably why no one noticed us at Sun 'n Fun). The electric starter is also a plus for people like me who developed "Onan Elbow". Incidentally, it started on the first hit after sitting for one week in 15 degree weather with normal choke and no priming necessary.

There is much more to say about our air-cooled AED engine, but some space should be reserved for the other "Mystery Quickie". That would be Lanny Rundell's, with AED's 72 hp engine based on Kawasaki's liquid cooled one. Lanny did a fine installation for the prototype, and it looked good. Lanny is a Quickie dealer in Louisiana.

Enclosed are two pictures at Sun 'n Fun because I agree that if you don't contribute, don't expect someone else to find a photo and words about your baby! (We have previously printed a picture of N4WH. ED>)

Bill Herzog, 1038 Bristol Ct., Northville, MI 48167

I'm sure I am not the only one building a Q-2 on a budget, so for others in the same fix, here's how I solved part of the avionics problem. I built a Radio Systems Technology 720 channel navcom. It made a fantastic project for the winter months. Instructions were clear and easy to understand with only one call necessary to the company. They were already aware of the problem and had an answer at hand. Quality of the kit was excellent with only three parts missing. Their instructions explain that some parts may be missing, but to continue with the kit and they will be installed by RST when the finished kit is returned for calibration. Calibration took about 12 weeks from the time I sent it back to when it was returned certified. I have no idea why, it takes that long, but it wasn't a problem for me since I'm not ready to fly anyway. I hooked it up in my garage for entertainment while building and had excellent communication with the airport two miles across town and through the local Safeway store. This was using the copper foil antenna embedded in my vertical stabilizer.

I highly recommend this product especially if panel space is at a premium as it has a hot mike intercom and a built in VOR head. $700 is their price and they are: RST, 13281 Grass Valley Ave., Grass Valley, CA 95945 or call 800-824-5978 outside California or 916-272-2203 inside CA.

Rick Becker #2570, Quincy, CA

With all the engine fiddling that goes on prior to or immediately after first flight some builders might be tempted to dispense with the chore of re-attaching the cowling when only a quick trip around the pattern is needed. DON'T DO IT.

You cannot only overheat the engine and warp the heads (even on prolonged taxi) but the drag forces may also become so large that your aircraft performance is inadequate, marginal or even catastrophic. We've already had one builder make this mistake (he's now rebuilding). Learn from his mistake.

Jim Masal (#457)

(Although not from a member, we are printing this thought-provoking letter which arrived in response to a survey card we sent to "suspected" flying Quickie/Q-2 builders. EDITOR)

For several days I resisted the urge to respond to your inquiry in a manner that has long tempted me.

Let me begin with an anecdote: Many year ago (1968), as I contemplated my first timid steps into the homebuilt arena, I ventured to a small airport near Troutdale, Oregon, where there was to be found a large group of active builders. I introduced myself and stated my purpose in the visit. An old timer sitting by a coal stove, discarded his chew and said, "Well get ready young feller. You are about to meet the greatest assemblage of crooks, phonies, fakes, bums, charlatans, liars, cheats, etc, that the world has ever seen".

I should have listened to him and turned to growing orchids or something.

I proceeded, however, and eight months later, $816 later, much much trauma later, I ended up the proud owner of a Jeanies' Teenie I.

During the process, I learned much: one must pay the supplier to even tell him about the kit (the usual $10 to $25 for the so-called information packet, usually a cheap offset-printed pamphlet costing a few pennies to create). Then the real trauma: always CERTIFIED funds up front, after which the supplier gets off his lazy butt and tries to persuade his sub-suppliers to get off their lazy butts, who try to get their sub-suppliers off their lazy butts and get the material to the buyer.

Hundreds of dollars in long-distance phone calls, frustration the human heart should never be called upon to bear, etc. etc. etc. eventually add up to the dream, and the airplane. From the $816 JT through a BD-4, to the $13000 Q-2, I have not met a single person or firm with whom I enjoyed my dealings.

Which brings us to recent inquiries. Several months ago, I received a request to provide complete information on a major accident caused by the original Q-2 canard getting wet. Complying with the request would have taken several hours of writing. I am sure it would have added reader interest to the publication, would have put more money into the bank account of the publisher. I noted that the requester did not offer me a complementary subscription to the publication, not even one copy, not even one 20 cent stamp, not even one envelope.

I trash canned his request.

Now this (QBA's) inquiry...

Ralph D. Hess, Miami, FL

Comments, anyone? ED.

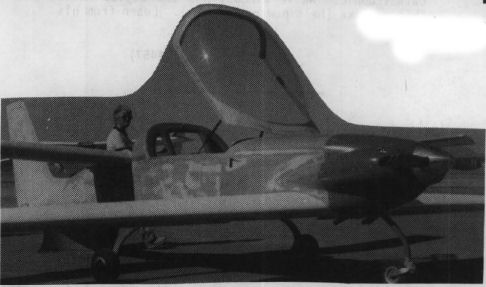

N83QR UPDATE

Three views of N83QR

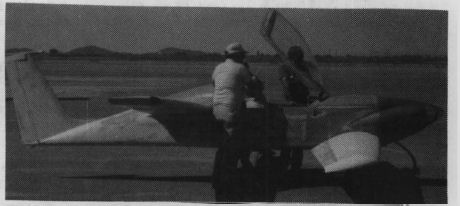

Two views of the TRI-gear DRAGNONFLY

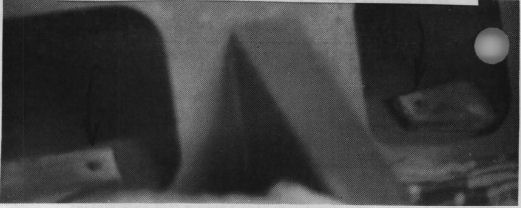

View from cockpit looking aft thru seatback - note gearleg attach points.

Builder Ron Gowan finished rebuilding his Q-2 after his second crash in November - all the while grumbling under his breath about Sheehan and QAC. This time he incorporated inboard wheel pants, a Dragonfly tailspring and 50% more rudder. We have been anxious to see how these changes would work out.

After fighting the same frustrating supplier battles that Mr. Hess describes in his letter, Ron was ready to go just before Thanksgiving. As he test started his C-85 engine the first time after the crash, it backfired and he got a fire under the cowling. The fire destroyed the cowling AND Ron's dwindling patience with this aircraft. Last week he came back from Mojave with Long-Eze plans. Q-2 carcass for sale.

LANDING GEAR ALTERNATIVES

We had a very educational visit to Eloy, AZ during the annual "Dragonfly Swarming" this year in October. The swarm was small - 3 - but we thank Rex Taylor and his charming wife Phyllis for a very worthwhile time. We spent a day at HAPI/VIKING and a day in Andy Marshall's outstanding traveling composite materials seminar. We'll report more details on these events next issue but:

We saw detailed plans for the Dragonfly inboard gear legs, and we saw the Tri-gear Dragonfly of Mike Quigley doing taxi tests and runway "crow hopping". QUICKTALK #17 shook a lot of alternative gear enthusiasts out of the bushes.

INBOARD GEAR: The Q-2 airfoil is thicker than the Drangonfly's which is thicker than the LS(1). The gearleg fitting would work in the thicker GU but not as well in the thinner LS(1). Furthermore, it wouldn't work with the carbon spar tube and would not retrofit in the GU because the Dragonfly gearleg fits into a mid-wing "C" shaped carbon shear web layup like so:

The Q-2 shear web occurs more aft on the canard and faces forward, so you can see the problem. Another wing, built differently, is required.

TRI-GEAR: This arrangement looks surprisingly nice after you walk around it a couple times. Our impression is that is could be made to fit in a Q-2 without being a major undertaking - course you would have to call it something other than a Q-2. The nose strut essentially bolts to the firewall and has a castering nose wheel. The main gear legs look like a Vari-Eze main gear bow that has been split in half for 2 separate legs. These are then bolted to a fibreglass gearbox that extends across the fuselage just behind the seatback bulkhead. Just how this gearbox was designed and built was not yet open to discussion, but it can be an add-on to flying Dragonflys and so we speculate, Q-2's also.

The guys at TASK RESEARCH have built and will be flight testing this gear, and Mike Quigley told me that the main gear may end up as a new one-piece design after they get into the test program further. Just before we went to press, Rex Taylor told me that this gear "is not ready yet". Furthermore, Taylor is not in any way interested in developing this product for anything other than his Dragonfly.

You can order a PDF or printed copy of QuickTalk #18 by using the Q-talk Back Issue Order Page.