Tri-Q Anhedral Removal LS(1) Canard

- Details

- Category: TriQ Plans

- Published: Wednesday, 22 December 2010 11:25

- Written by John S. Derr

- Hits: 5722

Support the canard right side up on a flat table. Mark thecenter line, BL00, all around. Measure 1/2" on either side of thecenter line on the top surface, slightly less at the leading edge.Mark the "V" shape for the cut down to the bottom of the carbonspar.

Remove the inner elevator pivots. Use cylindrical and taperedhigh-speed steel cutters in the Dremel to remove the glass and floxradius. Start a hack saw cut at one end to start a crack, thengently hammer the phenolic back and forth until the cr.ack propagatesand the pivot falls off.

Using a circular saw with a masonry blade, or a sabre saw, cutthe notch as deep as the saw permits. Finish with a small hand sawabout 2" around the leading edge and through the spar at the rear.Once cut, it will tend to fold back onto the tips so make sure it issupported well. Don't cut through the bottom skins yet, because whatremains will help you somewhat in keeping it jigged. The object isto get the bottom surface flat or slightly lower in the center, butkeep the top surfaces sloping down a little toward the tips.

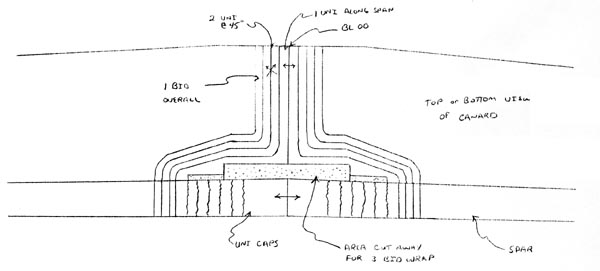

Remove the skin and foam around spar for 7" on both sides ofthe center cut, and to 10" on top and 9" on bottom to expose the sparcaps. Remove the skins over the spar caps, and then the caps downto the bid wrapping. Use 1" and 1/2" chisels. Start the chisels atthe saw cut and remove a strip of uni about 3-4 layers at a time.Work slowly and carefully, and stop at the bid. Use some coarsesand paper to smooth off the spar in preparation for the new layers.

Fit the spar ends as close as possible. Micro the cores together.Flox the spars together and wrap with one narrow bid tape to hold ittogether. Check to make sure both sides are level. Sand the bidtape and make the spar joint even, no joggles. Cut glass for bidwrap and spar caps as per original plans.

Lay up the 3 bid wraps and all those uni caps specified in theplans. Sand the spar caps and skins and micro the cut to smooth itout. Level the bottom by sanding through the remaining skin along thecenter line. Micro this area to smooth it out.

Mark areas to be glassed (4 lines 1" apart in a "T" shaped area,top and bottom). Jig canard vertically on the TE so you can glassit from spar to spar around the LE. Cut glass for 3 layers uni (2@45°and one along the span) plus one bid over all, both top and bottom.Use peel ply if you have it for the overlaping next set of skins.

Remove peel ply and sand overlap area. Fill gap between sparand foam cores with X-40. Jig canard on LE and glass the TE around thespar, overlapping the previous lay-up. Peel ply area for elevator pivots.Re-fit and mount inner elevator pivots.