Q2 Plans Chapter 16 Page 16-03

- Details

- Category: Q-2/Q-200 Plans

- Published: Friday, 05 May 2006 20:05

- Written by Quickie Aircraft Corporation

- Hits: 3257

|

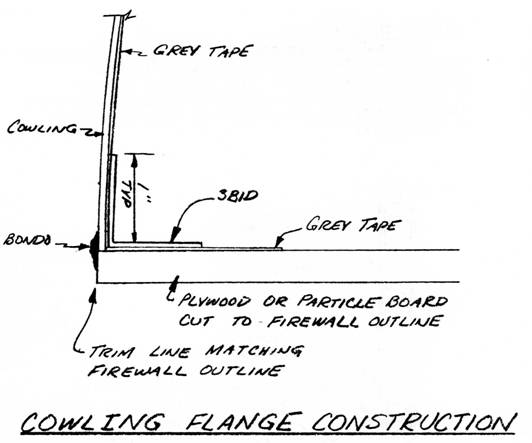

COWLING FLANGE CONSTRUCTION

..... In this section, you will make the flange that attaches the cowling to the firewall. This flange will fit around the entire circumference of the firewall. .....First, use masonite, scrap plywood, or particle board to make an accurate template of the firewall. This template will allow you to form an accurate flange that will produce an excellent fit on the cowling. .....Bondo the cowling to the template at the outside edge, so that the cowling is draped like it will be when mounted on the firewall. It is necessary to do only one-half of the cowling at a time. .....Next, using grey tape, protect two inches of the inside cowling skin and 2" of the template inside surface, as shown. Laminate a 3 BID flange around the inside joint, overlapping 1 inch onto the inside cowling skin and the inside template surface. Allow to cure thoroughly to prevent future warpage. .....Repeat the process with the other half of the cowling. .....Remove the flanges from this simple "mold" and clean off the grey tape from the cowling.  TRIMMING THE COWLING

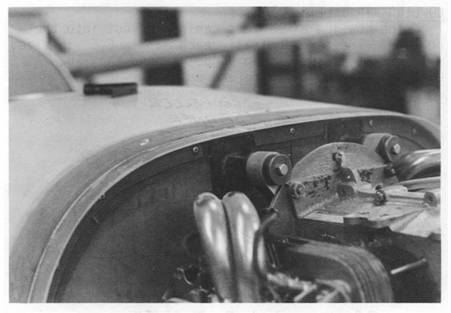

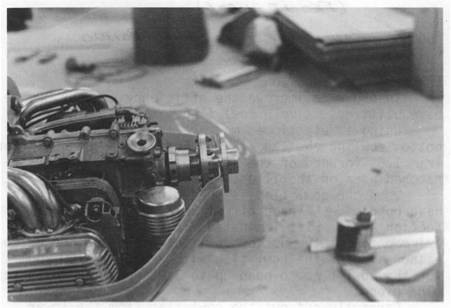

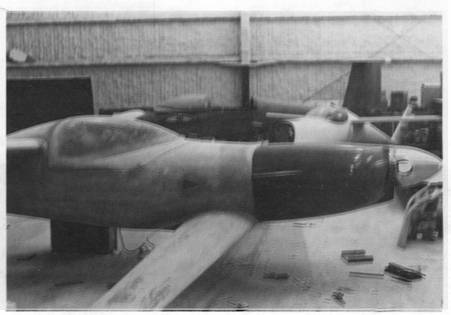

..... The cowling is shipped to you preformed and rough trimmed to size. Final trimming can only be accomp¬lished with the engine mounted on the airframe and the propeller spinner available for fitting. Do not proceed further until that has been accomplished. .....Previously, you fabricated two cowling mounting flanges, one for the top cowling half and one for the bottom cowling half. Locate these two flanges. .....It will be necessary to cut a hole in the nose of the cowling fon the crankshaft to pass through, The hole should clear the crankshaft by only 1/4" to minimize air leakage. .....The fitting of the cowling is a trial and error operation. By fitting the spinner to the crankshaft flange, you can determine the necessary cowling length to allow only a 1/16" gap between cowling and spinner. Obviously, the cowling is trimmed as necessary on the aft face. Once the length has been arrived at, it is necessary to mount the cowling mounting flanges using BSP46 rivets on about a 3.5" spacing. The flanges are located so that the cowling will fit flush with the fuselage after mounting. The rivets holding the flanges also serve to mount the fiberfrax and aluminum sheet to the firewall. .....Some trimming of the junction of the two cowling halves may be necessary to achieve a best fit.     |

||||

|

||||

PAGE

16-3 |

||||