Q2 Plans Chapter 17 Page 17-03

- Details

- Category: Q-2/Q-200 Plans

- Published: Thursday, 04 May 2006 20:05

- Written by Quickie Aircraft Corporation

- Hits: 3572

|

HEADER TANK INSTALLATION

..... It is much easier to install the header tank prior to mounting the canard to the fuselage. .....Install the header tank using 2 BID and flox where it meeTs the inside fuselage skin. .....As a reminder, prior to permanently mounting the fuel header tank, make sure that it will not interfere with instruments, feet, rudder pedals, engine installa¬tion, etc. In order to maximize the fuel quantity_ it has been made a tight fit in the forward fuselage.  HEADER TANK FUEL GAUGE

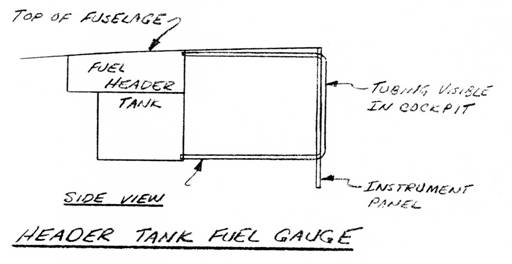

..... It is necessary for the fuel header tank to have a fuel gauge to detect any failure of the fuel transfer system that would result in a reduced level of the header tank. .....A very simple arrangement of clear plastic tubing is used to create a sight fuel gauge. It is floxed in place at the top and bottom of the fuel header tank, and then run aft through the instrument panel into the cockpit where it is turned vertically as shown. .....Later, calibrate the gauge with the fuselage levelled with respect to WL15 by adding fuel in one gallon increments and marking the clear plastic tube. A similar calibration is performed on the main fuel tank guage. .....It is important to note that the gauge will only be accurate while in straight and level flight. Particularly in the case of the fuel header tank guage, small changes in aircraft attitude will make large changes in the indication of fuel quantity. The fuel header tank gauge should be used only to verify that the fuel header tank is maintaining a full level in straight and level flight. .....Also note that the fuel header tank gauge cannot be installed until after the instrument panel has been installed.  FUEL SYSTEM INSTALLATION

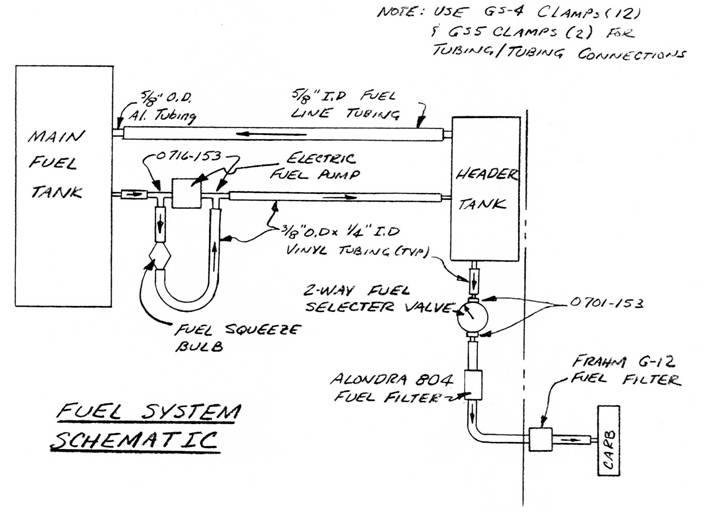

..... Included with this section is a schematic of the fuel system for your Q2. It is really quite simple. .....Both the squeeze bulb (backup fuel pump) and the fuel shutoff valve must be capable of being actuated by the pilot while seated in the cockpit. However, it is important that the fuel line to the carburetor from the header tank travel a minimum distance. Therefore, it will probably be necessary to fabricate an extension on the fuel valve handle such that the fuel valve can be located near the firewall, in order to reduce the length of the fuel line to the carburetor. .....The two filters shown are very important. They must be checked after every engine run for the first 20 hours. Regardless of how good of a job you expect to accomplish in keeping contaminents out of the two fuel tanks, particles will travel through the fuel lines and must be removed. This is a safety-of-flight issue. The vibration of taxiing will break loose particles for several hours. Do not ignore fuel contamination problems.  |

||||

END OF CHAPTER |

||||

PAGE

17-3 |

||||