Q1 Plans Chapter 13 Page 13-1

- Details

- Category: Quickie Plans

- Published: Monday, 12 May 2008 10:28

- Written by Dan Yager

- Hits: 2111

The main wing is permanently attached to the fuselage with 2” BID tapes on both the inside and outside of the fuselage, and 2” UNI tapes on the inside.

Begin by leveling the fuselage, both longitudinally using WL15, and laterally using the longerons.

The procedure for fitting the main wing is one of fitting, then trimming, then refitting until the main wing fits properly.

Some important considerations are:

- When the fuselage sides were made, the BLOO main wing template was used to approximate the cutout. This cutout must be trimmed to make it fit the actual wing.

- The level board on the main wing must be level when the main wing is in the proper position. Recheck the fuselage leveling also.

- Avoid having to use lots of flox to fill voids during the mating process by being careful in the trimming.

- Check to make sure that the main wing centerline is on the fuselage centerline.

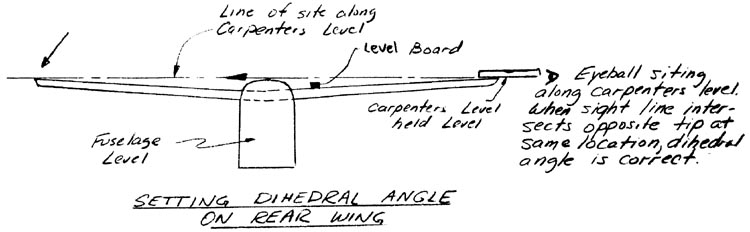

- Check the dihedral of the wing by siting across the span with a level as shown.

When everything is ready, dull the glass wherever the fuselage and wing will meet, and then mix up some micro for the areas on the left and right fuselage sides where the mating occurs. Paint pure epoxy on the front and rear faces of the wing where it will meet the FS89 bulkhead and the seatback bulkhead. Trowell on plenty of flox to fill any voids between the bulkhead and the wing. Lower the main wing onto the fuselages verify good squeeze out and then remove the excess.

Now, check the level of the fuselage and wing again, as well as the dihedral angle. When satisfied, leave the aircraft alone for one day in order for the epoxy to cure.

Then, you can begin applying the BID and UNI tapes that provide the real strength. Note that two tapes are used everywhere.