Q1 Plans Chapter 7 Page 7-10

- Details

- Category: Quickie Plans

- Published: Sunday, 12 October 2008 01:00

- Written by Dan Yager

- Hits: 2978

ASSEMBLING THE FUSELAGE

Before beginning this step, you should have both fuselage sides, the fuselage bottom, and the fuselage aft top piece, contoured and glassed on the inside. Also, the Firewall and all fuselage bulkheads should be completed.

Jigging the basic fuselage will require about 4 hours of work.

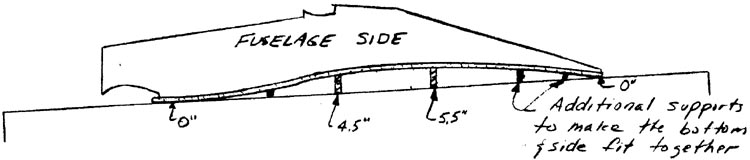

Begin by placing the fuselage bottom on the table and elevating it off of the table at the following STA:

STA | HT. OFF TABLE |

40 | 0" |

90 | 4.5" |

125 | 5.5" |

172 | 0" |

Take one of the fuselage sides and trial fit it onto the fuselage bottom. Use bloc1s of wood and foam to get the bottom closely fitting the side profile.

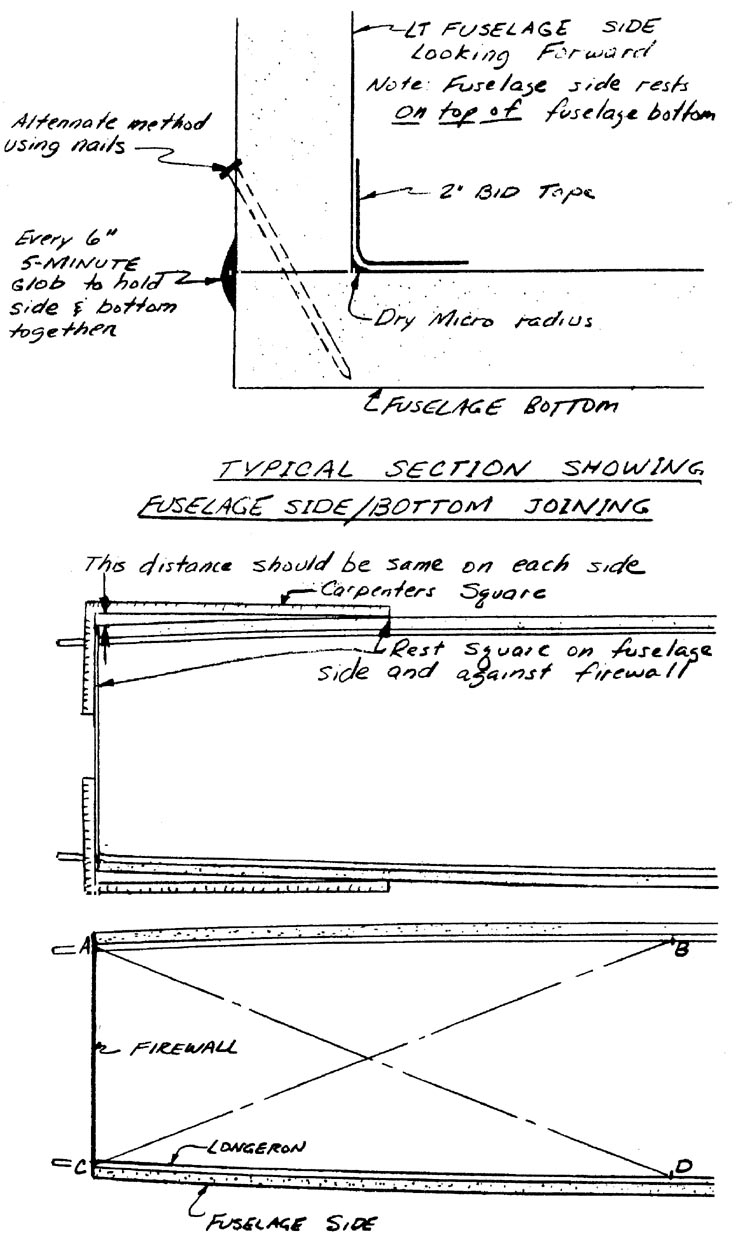

Remove the side, mix up some slightly dry micro, and apply it to the side and the bottom where they meet from the front back to STA70.

In the forward fuselage area, line up a similar STA on both the bottom and the side and join the two pieces. A good basic reference is the forward face of the fuel tank. Don’t worry that the STA toward the back will not line up. This is due to the curvature of the fuselage bottorn. Verify good Micro squeeze out.

Next, while one person holds the side in place, have a helper mix up a small batch of 5-minute, and gather up some small nails. Dab 5-minute about every 6 inches on the outside to hold the side and bottom together. After this has been accomplished all of the way to the tail, the side should stand vertically without holding it. An alternate method is to use nails to hold the two pieces together.

Look along the inside seam of the bottom/side and verify a good fit. Verify good squeeze out on the Micro at the forward fuselage area.

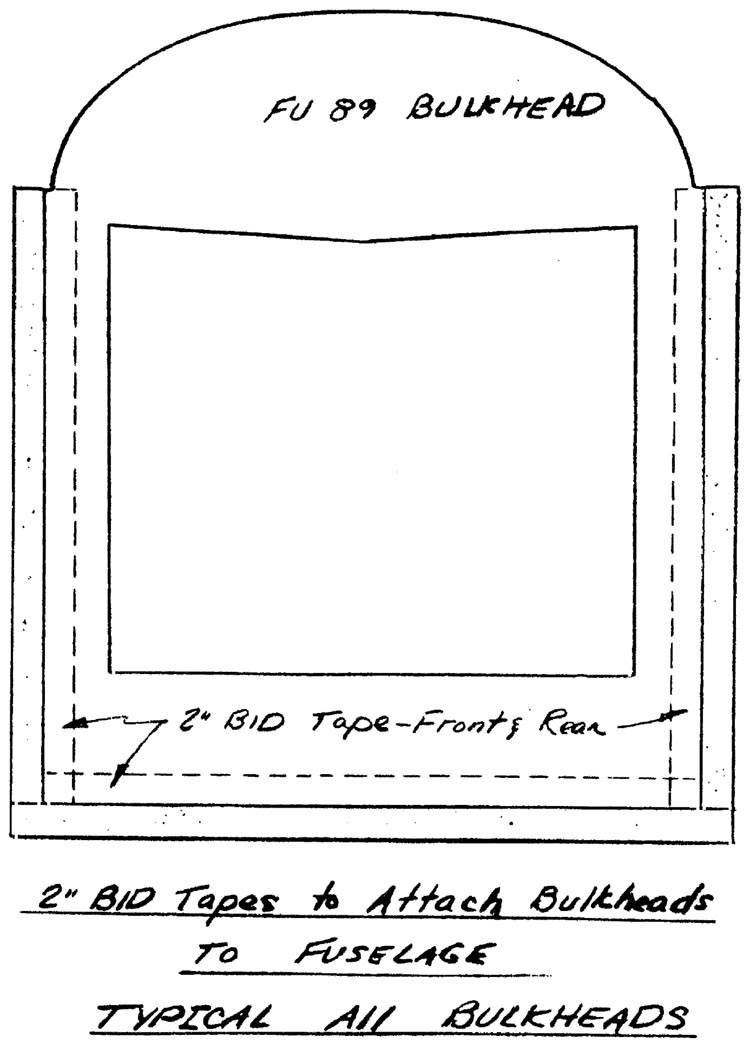

Lay a dry Micro radius along the inside joint all the way to the tail. Use a 2” BID tape to join the side and bottom together on the inside all the way to the tail. At this point, the angle between the side and the bottom should be about 90 deg.

Carefully repeat this operation with the other fuselage side. Be sure that the same forward fuselage marks are used to line up the side and bottom so that the two sides are lined up equally.

Next, fit the firewall and trim and sand where necessary to make it set “square” with the fuselage. Attach the firewall to the fuselage with two 2” BID tapes along each inside juction.

- Measure back from the firewall along the longeron 50” and place a mark. This is segment AB.

- Repeat for the other side CD.

- Measure AD and CB; these two lengths must be equal if the firewall is square with the fuselage.

- If not equal, adjust fuselage until firewall is square.

CONTINUED ON NEXT PAGE