Q1 Plans Chapter 9 Page 9-10

- Details

- Category: Quickie Plans

- Published: Monday, 22 September 2008 01:00

- Written by Dan Yager

- Hits: 2683

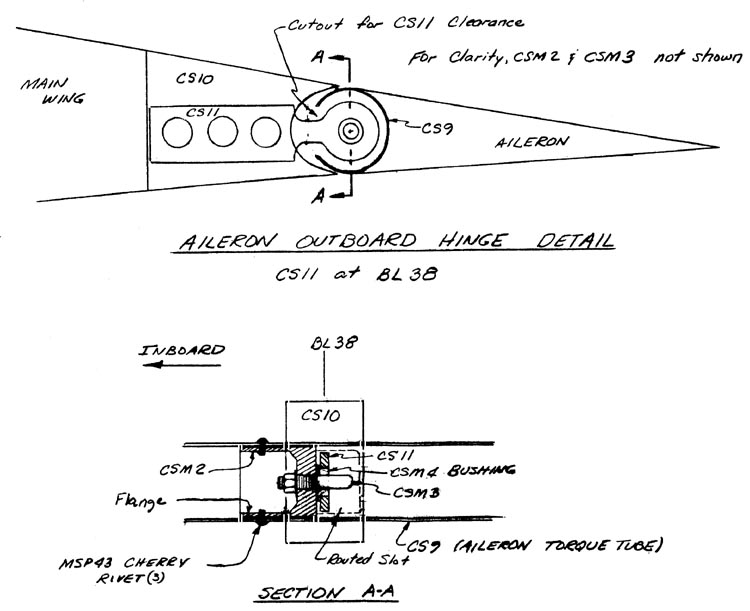

The outboard pivot is mounted at approximately BL38.

Screw CSM3 into CSM2 and retain it with a locknut, as sho\ün. It must be tight. Round the end of CSM3 slightly.

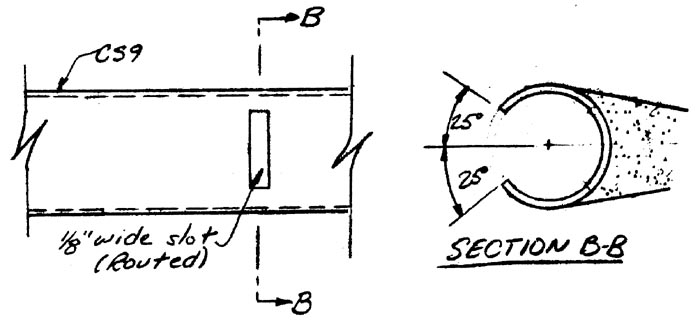

Measure 28” outboard from the in board end of the aileron(that’s the end which still has CS9 visible). Using a router bit, route a slot 1/8” wide for about plus or minus 25 deg. of rotation. (see sketch). Next, insert CSM2 into CS9 with the flange pointing inboard You may have to sand CSM2 to get a snug .f it. Push CSM2 outboard thru the tube with a stick until you just see it flush with the routed slot. Rivet 3 MSP43 cherry rivets to hold it in place.

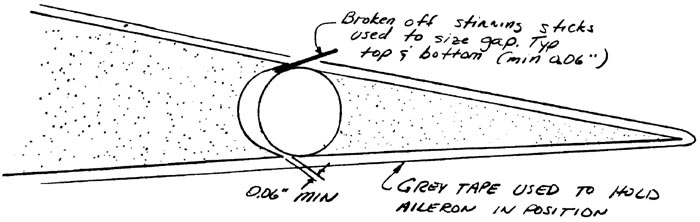

The routed slot must be opened up so that CS11 can slide off of CSM3 and out of CS9 while remaining perpindicular to CS9. This means that the slot must be about 0.5” to 0.6” wide. Also, check to see that CS11 can rotate about CSM3 approximately 25 deg. in each direction while inside CS9. Debur the slot and round all corners to avoid stress cracks. Do not make the slot any larger than you have to.

Repeat this procedure with the other aileron. Be careful that the flange on CSM2 points inboard so that CS11 will slide off CSM3 as the aileron is moved inboard

CS1O is a shaped block of red foam which is mounted in the wing. Later on, CS11 will be mounted in CS1O permanently. To find out where CS1O should go, tempor arily set each aileron in its approximate position on the wing, with the inboard aileron edge at EL1O. CS1I should be against CSM2. Now you can mark where CS1O must go to capture CSI1. Remember that to remove the ailerons, they are moved inboard(while CS11 remains fixed in CS1O) until CSI1 slides off CSM3; then the aileron can be pulled off. If you don’t stand back and think about this, you are likely to error during the installation.

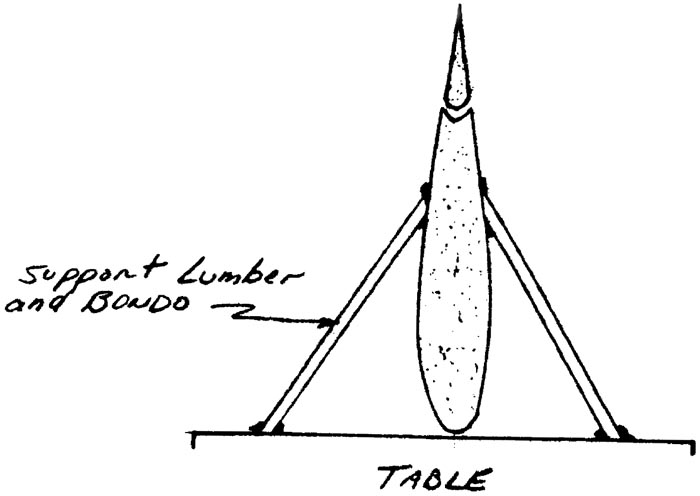

Once you know where CS1O goes, remove the blue foam of the wing core and install CS1O with dry micro, and sand to remove bumps and joggles. CS11 will be per manently installed into CS1O later during the aileron installation and rigging.

One BID over CS 10, top and bottom is used to permanently attach CSIO to the main wing