Q1 Plans Chapter 7 Page 7-14

- Details

- Category: Quickie Plans

- Published: Wednesday, 08 October 2008 01:00

- Written by Dan Yager

- Hits: 2871

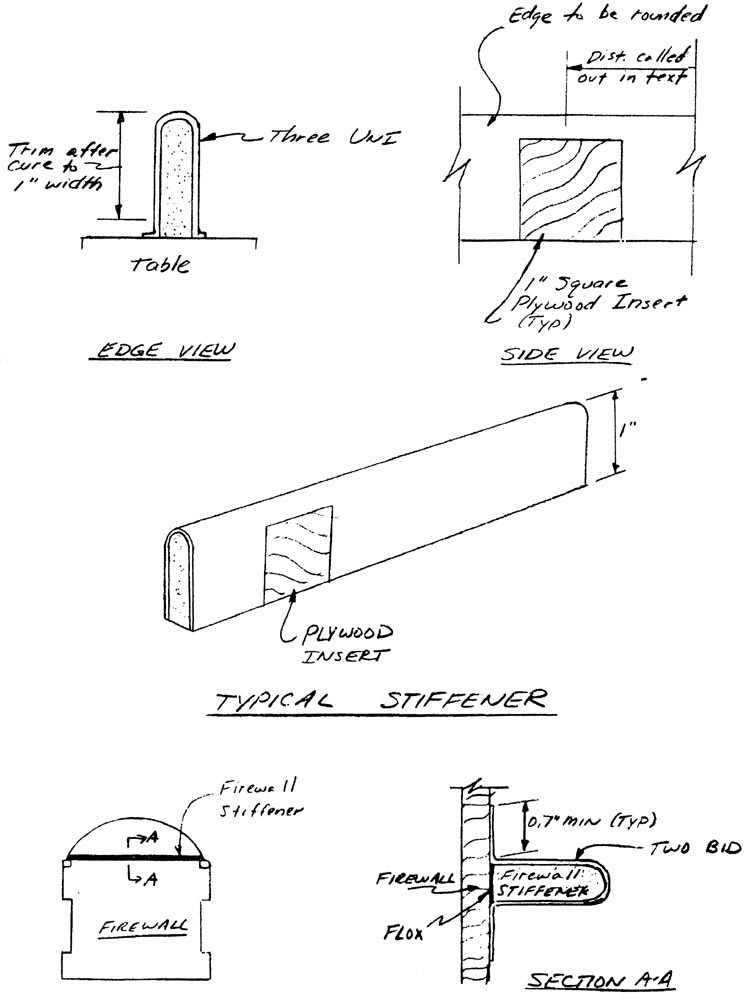

STIFFENERS

In this section, you will make the firewall stiffener, and the left and right canopy stiffeners. The canopy stiffeners will be used later in the canopy section.

Begin by cutting three pieces of orange foam with the following dimensions:

- 1.2” x 18” (Firewall stiffener)

- 1.2” x 25” (Lt. canopy stiffener)

- 1.2” x 43” (Rt. canopy stiffener)

Mark each piece with the proper name and mark one end of the canopy stiffeners as the aft end.

Before glassing, some plywood inserts need to be located in the canopy stifferners. The firewall does not receive any of these.

The right side canopy stiffener gets plywood inserts of 1” square at 6.9”,1l.2”, 29.9”, and 34.2” forward of the aft end. Remove the orange foam, insert the inserts with micro, and make a smooth transition with the orange foan.

The left side canopy stiffener gets a 1” x 2” plywood insert 19” forward of its aft end, and 27" forward.

So that the glass will layup around the edge, round one of the long edges of each stiffener.

Set each stiffener vertical on the table, held in place with a few dabs of 5-MIN. The remaining square edge should be the edge on the table. Lay up three UNI on each stiffener, with the orientation running along the length of the stiffener. Since the end resting on the table will be trimmed, you don’t have to worry about the part of the stiffener within .2” of the table.

After the layups have cured, trim the square edge so that the width of each piece is about 1”.

Mount the firewall stiffener with two BID as shown. The stiffener is located on the aft side of the firewall (i.e. the cockpit side) and rests on top of the longerons. Use the BID to join the stiffener to the longeron.