Q1 Plans Chapter 7 Page 7-12

- Details

- Category: Quickie Plans

- Published: Friday, 10 October 2008 01:00

- Written by Dan Yager

- Hits: 2852

GLASSING THE OUTSIDE FUSELAGE

Glassing the outside fuselage skin will consume about six manhours. At least two people should be present; preferably three so that one individual can just mix the epoxy.

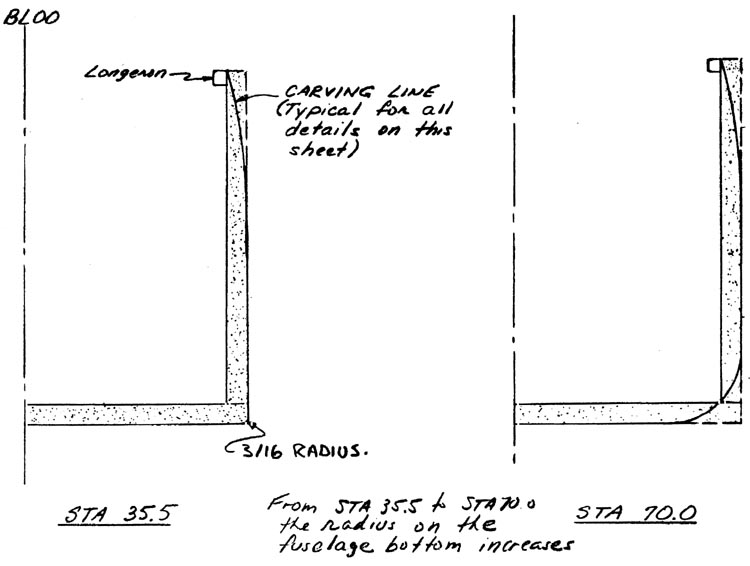

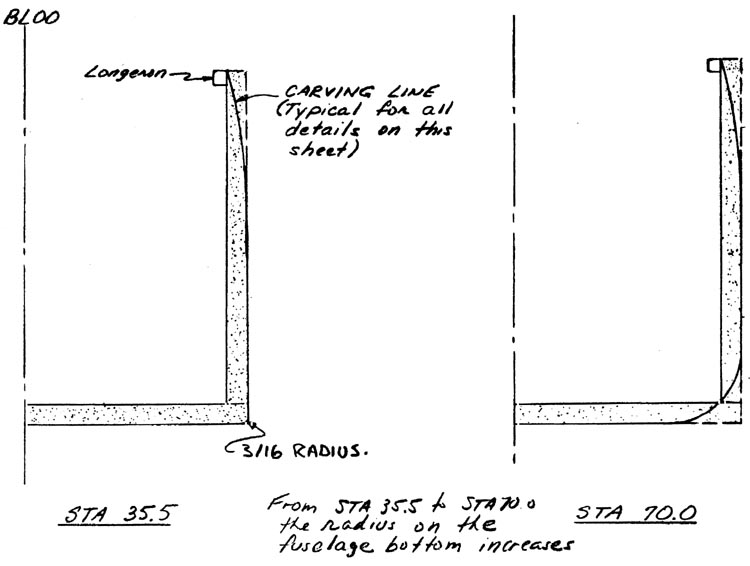

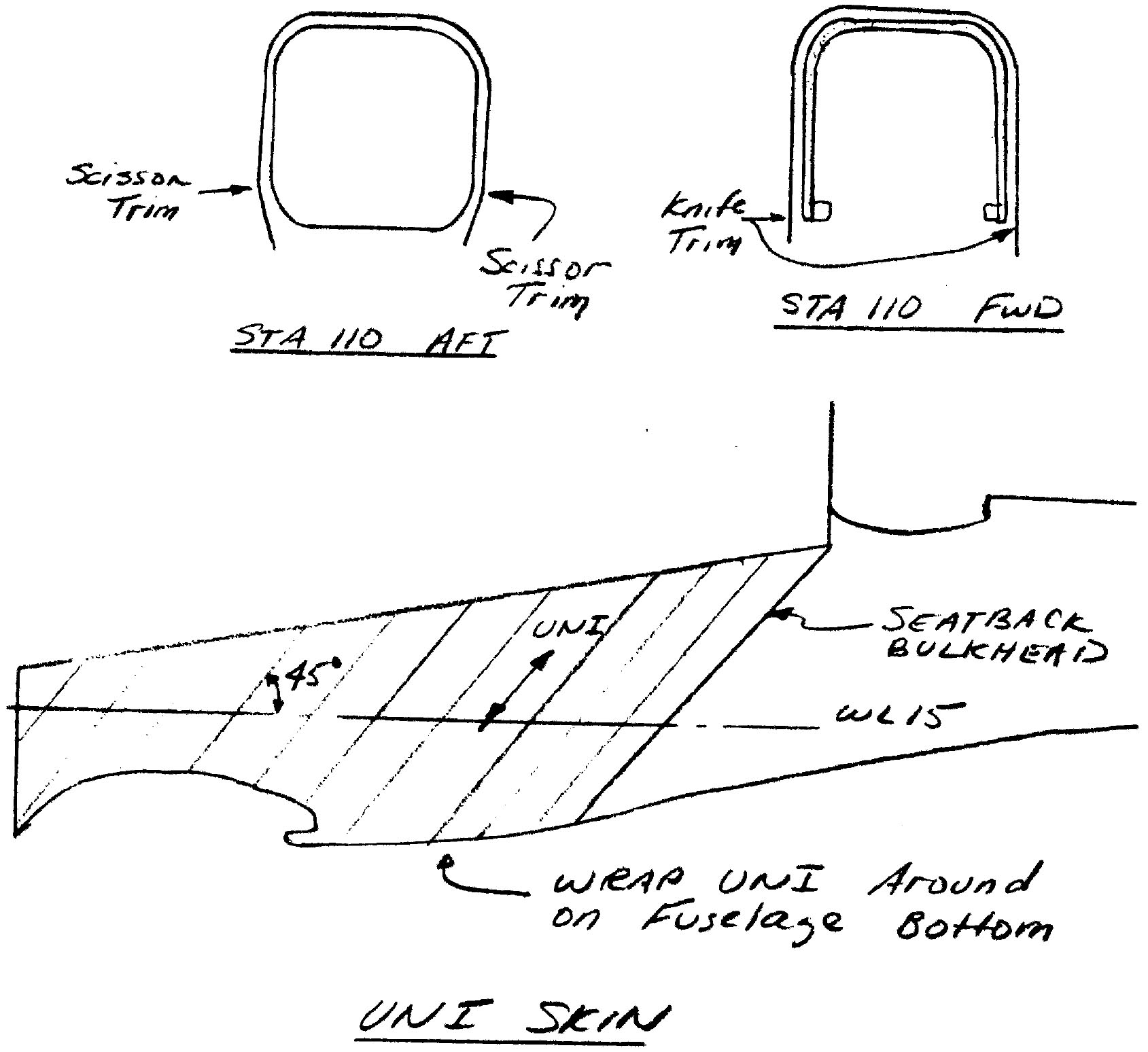

The fuselage receives one ply of BID over its entire length plus one ply of UNI at 45 deg. to WL15 from the seatback bulkhead area forward. The glassing progresses from the aft fuselage forward. The top of the fuselage as well as the longerons, are glassed after this first iayup has cured.

NOTE: Before glassing the outside of the fuselage, install the 1” square x 1/4” thick aluminum plate for the fuel drain valve installation later, See sheet 7-6 and sheet 12-1.

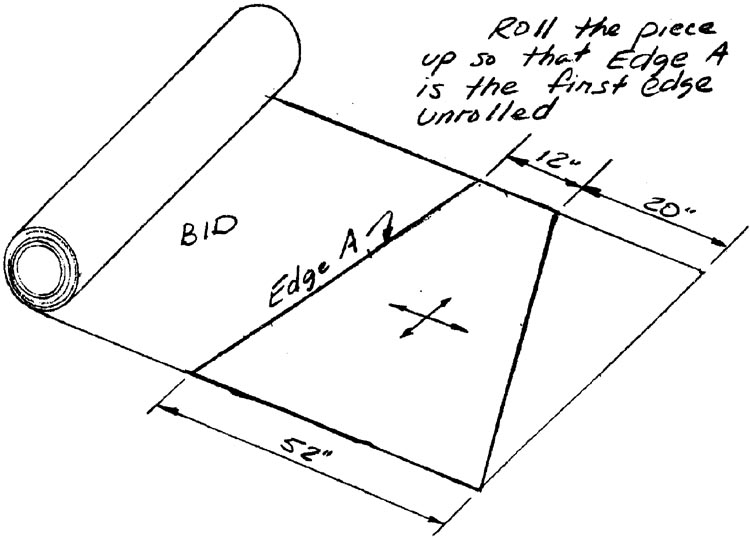

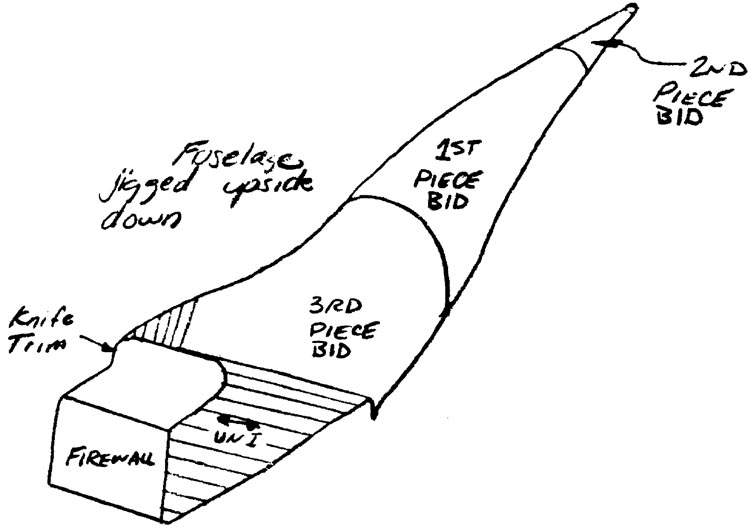

Begin by jigging the fuselage level in an upside down position. Cut a piece of BID with these dimensions:

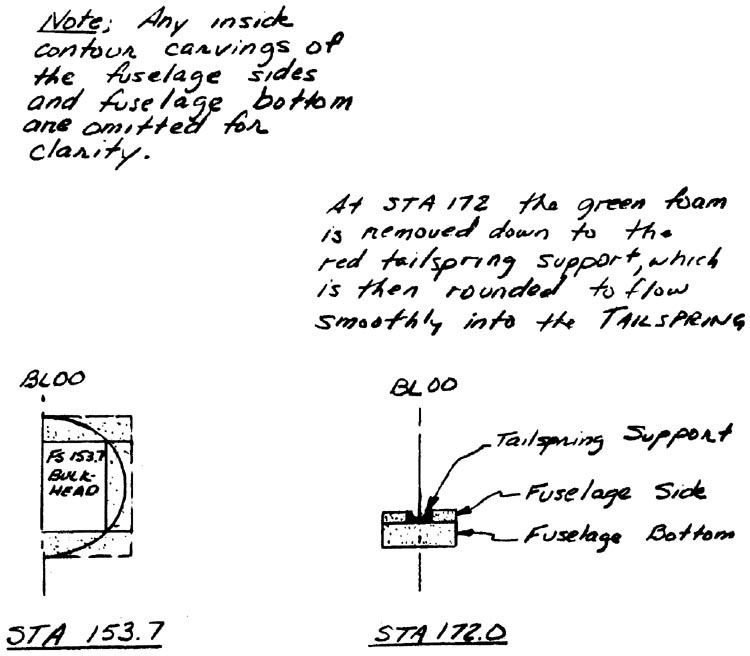

This piece wraps around the fuselage sides and bottom from approximately STA 110 to STA 154. Begin by placing Edge A parallel to the top fuselage line and along the corner where the inside fuselage tape has been exposed by previously removed urethane foam. Of course the 52” long edge should be the one at STA11O. Once that Edge A has been attached all the way back to STA153, begin to unroll the piece around the fuselage accross the bottom to the same corner on the other side. Remember that since the fuselage is jigged upside down, that the fuselage bottom is actually on top. Also, be liberal with the micro slurry that you cover the green foam with prior to laying the cloth down.

After wetting out and squeeging this first piece of cloth, you can cover the fuselage aft of STA 153 with scrap cloth and 1” overlapping.

Next, cut out additional BID for the area forward of STA11O. Remember that the cloth should be at about 45 deg to WL15 on the sides, that 1” is the minimum overlap, and that wrapping the cloth around the fuselage from longeron to longeron will be the easiest way. The cloth should be knife trimmed even with the top of each longeron.

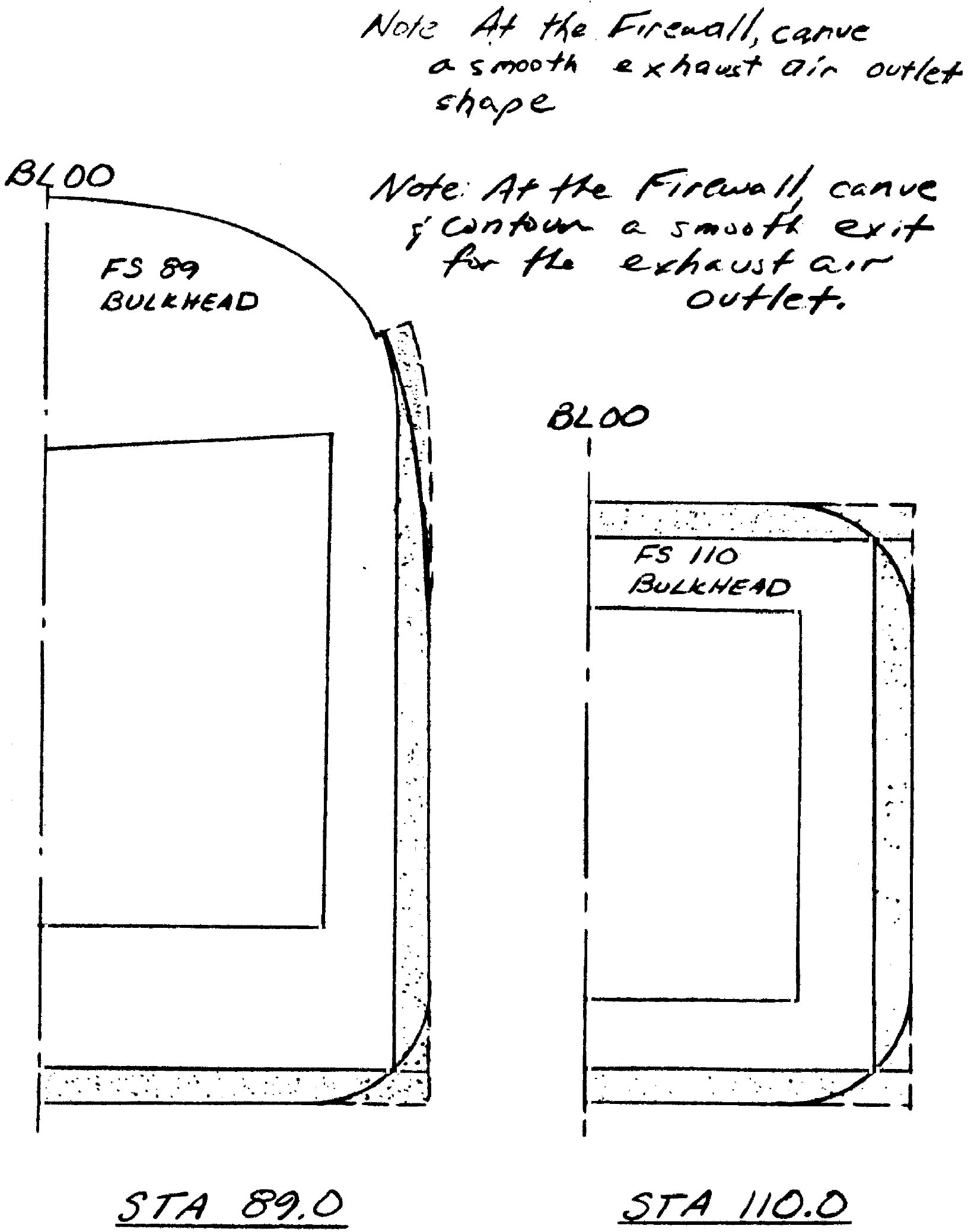

The UNI is placed at 45 deg. to WL15 and is placed forward of the seatback bulkhead area to the firewall. Two 2” BID tapes should be used on each side to join the forward face of the Firewall to the outside fuselage skin.

Peel Ply all overlaps and knife trim the longeron areas before quitting.

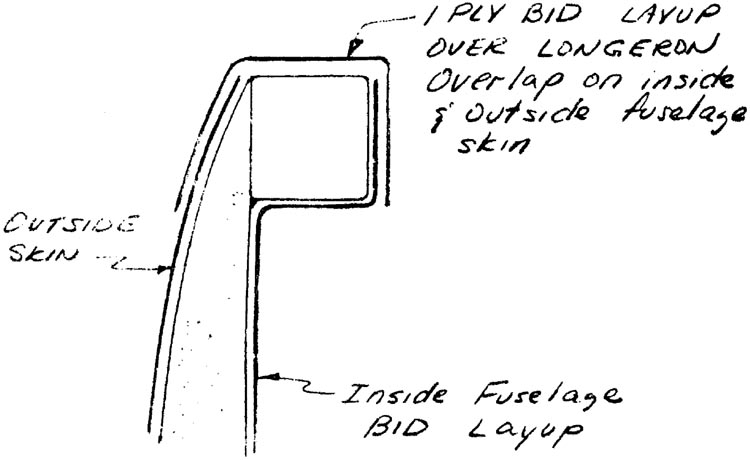

Also at this time, layup one ply BID around each longeron. Peel ply this layup also,

Since only one ply of BID is on much of the fuselage, it is very important never to sand that ply.

Once this main layup is cured, the fuselage can be flipped over upright and the aft top fuselage glassed with one ply of BID at 45 deg. to BLOO. Use a 1” overlap on the BID from the previous layup. Peel ply the overlap joint.