- Details

-

Category: Q-Talk Articles

-

Published: Wednesday, 23 December 2009 16:24

-

Written by Dan Yager

-

Hits: 3266

As you've probably read by now, this will be Doug Humble's final issue of Q-talk. I joined QBA just as Doug took over as editor and I know many people (especially me) would like to thank and congratulate him for a job VERY well done over the past five years.

Reading through the back issues of Q-talk it's amazing to think about the amount of work put in by the previous editors to keep QBA alive and growing for almost thirty years! The fact that Jim Masal is responsible for 13 of those years is a testament to his character and sadomasochistic tendencies!

So, when Doug approached me in early 2009 to take over as editor for the Quickie Builders Association I was honored, flattered, and absolutely scared to death! Doug had witnessed my own dedication to providing information to the Quickie community through my website, and apparently liked what he saw.

Unlike many members of QBA, I don't have a background in aeronautical engineering. What I do share with most of you is a curious nature, and passion for flying and building airplanes. After six years as a Nuclear Electrician in the Navy, I graduated from Boston College in 2001 with a degree in Film and Computer Science. I earned my pilot's license in 2005, and have about 100 hours and a taildragger endorsement in my log book. I have been a Quickie enthusiast ever since I saw them advertised in the airplane magazines I pored over as a kid.

What all this adds up to is a humble (sorry Doug) philosophy about homebuilding. Namely, "build it per plans," but if the plans fail in some area, turn to people who are more experienced for answers. NEVER take your responsibility as manufacturer lightly.

I have spent the past four years not only tinkering on my own plane, but also cataloguing information about the designs and making it available to anyone who might need it. As I take over editorial duties for the Quickie Builders Association, my philosophy will be to simply continue doing that. I want to support the mission of QBA by sharing good, practical information, and make it easier for each member to share their own experiences.

With each editor change the Quickie Builders Association ultimately changes as well. This must occur not only to incorporate the specific skills of the editor, but also to incorporate new technology, and keep the qBa growing and responsive to member needs. This current transition will be no exception. Perhaps the most important and exciting change is that the Quickie Builders Association will be going 100% online beginning in January 2010. This means that the newsletter will now be able to incorporate feature rich content such as video and audio that just would not be possible in a printed format. Going online will also provide a much improved and instantaneous way to collaborate among members. In addition, this move will free up resources to provide benefits and value that have never been possible before.

Those of you that visit my site frequently may have experienced a lack of updates recently. In reality, Doug and I have been coordinating efforts over the past several months to bring all of the content that is currently on the quickibuilders.org website over to the new site. We're also working to make sure that traffic to the old site gets redirected properly, and that all of the software is updated and ready for us to "flip the switch" on January 1st. We have worked hard to make sure that you all receive the maximum "bang for your buck" and I am really excited to hear about what you all think about the changes and benefits. However, that's all I'm going to say (in print at least) about the benefits of membership going forward. To learn more, you'll have to practice going online yourself.

Simply visit:

http://www.quickheads.com/benefits.html

and let me know what you think. I look forward to speaking and sharing more with all of you online!

You can order a printed copy of Q-talk #138 by using the Q-talk Back Issue Order Page.

- Details

-

Category: Q-Talk Articles

-

Published: Monday, 28 February 2000 06:11

-

Written by Tom Moore

-

Hits: 3203

A current QBA member may have one free ad per month. It may be a maximum of five lines of type and will be edited to fit space available. Items advertised must be owned by the QBA member. The ad contact must be a member name. Ads will be run for TWO issues and then the ad must be resubmitted.

FOR SALE: Fully wired instrument panel for a Q2/Q200. Hobbs, needle ball, altimeter, VSI, O-220 A/S, Terra Tri NAV/COM, Narco AT-50 Xpndr, Tach, CHT/EGT gauge, Ammeter, Oil temp, Oil Pres., Warning lights, fuses, two eyeball vents. $1,995. Contact This email address is being protected from spambots. You need JavaScript enabled to view it.

FOR SALE: One Quart of Liquid Firewall. $25 covers S&H. Contact Bud Starnes, 5114 Hartmann Rd., Mt. Vernon, IN 47620, 812-985-2527 or e-mail n l This email address is being protected from spambots. You need JavaScript enabled to view it.

FOR SALE: Q-200 kit airplane, less engine and epoxy (went bad after about a year). Kit cost was $10,017 in 1984. The kit is zero percent completed. Will consider all offers. Call Rich Smith at 503-251-1032 or e-mail at This email address is being protected from spambots. You need JavaScript enabled to view it.

FOR SALE: Q-200, 690 TTAF&E, Terra 720 COM/NAV, Mode C, strobes, EGT, CHT, MP, new prop & key starter, 170 MPH. Excellent condition. $16,500. Houston, TX, 281-293-2491. This email address is being protected from spambots. You need JavaScript enabled to view it.

FOR SALE: CARBON FIBER SPARS - new, $500. Contact Kimbull McAndrew 403-254-2883, e-mail This email address is being protected from spambots. You need JavaScript enabled to view it.

FOR SALE: Zero time Formula Power Subaru. Best of the Best. Balance to 1 gm. Ported and relieved and flowed heads. Truck block. Contact Bruce Brown 504-395-7289.

WANTED: Photo copy of Quickie Q-1 owner's manual. Will pay costs and postage. Call Glenn 603-745-5005 or e-mail me at This email address is being protected from spambots. You need JavaScript enabled to view it.

FOR SALE: Complete (new) QAC hydraulic disc brake kit. Includes tires, tubes, wheels and mounting hardware, $200. Tailwheel, axle, QTW 5, 3 and M1 spring bracket and spring $100. Frank 770-978-2403 or e-mail at This email address is being protected from spambots. You need JavaScript enabled to view it.

FOR SALE: Tri-Q Zero time AF & Revmaster engine. FAA inspected & approved, LS1 canard, reflexor, Matco brakes, tinted canopy. Stored in Seattle, primed 100 hours to refinish. $7K. 281-244-4835 wk, 281-993-0981 hm This email address is being protected from spambots. You need JavaScript enabled to view it.

FOR SALE: TRI-Q-200 (Q-TALK issue #69) O-200 engine, 748 hrs SMO, 3 blade warp drive prop, Collins Micro-line, IFR panel, oil filter, reflexor. $21,500. Jimmy @ 956-546-4541, Marvin @ 956-381-2782, or Marvin e-mail This email address is being protected from spambots. You need JavaScript enabled to view it.

WANTED: Q200 kit - the more original the better. No engine required. Wing cores, carbon spars and canopy a must. Kit is required in UK so you must be prepared to crate it and ship it. Ian Molesworth, Tango4 Consulting, Intnl +44 411 378 562, UK 0411 378 562

FOR SALE: Q2 taildragger, Revmaster Q2, per plans. Major construction complete, wing and (LS1) canard are attached. Revmaster w/RevFlow carb, 0-time with vacuum pump (no pulley) also mounted. Firewall sheet metal mounted. Instrument panel with A/S, Alt., VSI, Vertical Compass, T&B, and AI. Oil Temp, Oil Pressure, Suction, EGT, CHT and OEM Tach. Whelen strobe, Wheels and brakes installed. Landing lights in wheel pants. Dual rudders. Dual fuel pumps. Fuel system complete. Partial surface finishing complete. Engine & panel mount, final assembly and paint to finish. Photos and building logs included. Also includes some worktables and extra hardware. $7900. Ormond Beach (Daytona) FL. Contact Kurt Van Dyke 904-676-7987

The QBA T-shirts with the image seen below are now available. The image appears over the left breast. The Quickie is colored RED and the lettering is black on a white Hanes BEEFY-T that is 100% pre-shrunk cotton. They come in sizes M, L, XL. The cost is $10 per T-shirt plus $3 for shipping. Add $1 shipping for Canada and $2 for international.

You can order a PDF or printed copy of Q-talk #80 by using the Q-talk Back Issue Order Page.

- Details

-

Category: Q-Talk Articles

-

Published: Wednesday, 23 December 2009 16:24

-

Written by Doug Humble

-

Hits: 3515

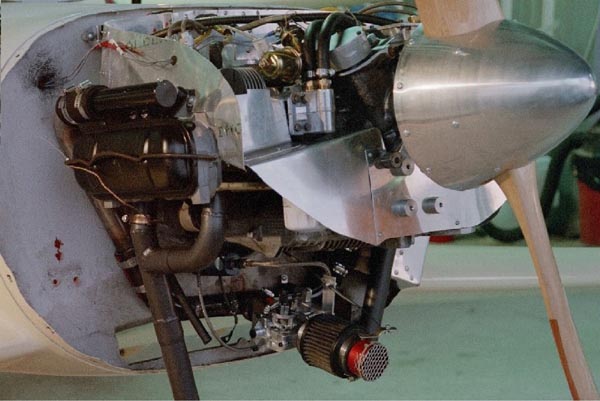

I always promised Dave Richardson an article on my VW Type 4 engine. Then he made me editor, so here it is Dave!

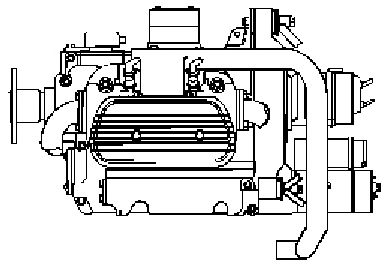

During my first Tandem Wing Fly-in at Ottawa in 1994, I was naive and looking for an engine for my Dragonfly project. Steve Bennett of Great Plains Aircraft Supply spoke and he made mention of VW Type 4 (T4) engine as an alternative to the VW Type one (T1) engine. It had a stronger aluminum case and could be build up to 90+ HP on a small budget. I was hooked.

Steve Bennett just so happens to live in Omaha where I reside, and I quickly found him out to become his next best friend. You see, I didn't take auto mechanics in high school and didn't know the terminology let alone how to tear down and put back together an "easy to work on" engine. Like I said, I was naive.

Fitting the T4 engine in the same space where once a RevMaster T1 hung, was relatively easy. The heads are larger so there are some items to be done on the pilot side to get it to fit under the Q2 cowling. The wire valve cover retainer must go. To hold the valve cover in place, I cut 2 hose clamps in half and mounted them with screws to existing holes on the heads. The two halves then come together to retain the valve cover. See picture below for visual detail. The front of the valve cover rubbed the cowling and prevented the cowling to fit. I used a hammer to dent the front of the valve cover enough for the cowling to fit. I was trying to use an existing cowling and if you have not fit the cowling yet, a builder could avoid the denting process.

The other item that I had to do to get the engine to fit under the existing cowl was to reduce the height of the intake manifold. I used the standard Great Plains Type 4 manifold but had to cut & re-weld them to minimize their height. This significantly reduces the ability to tighten the attach nuts and I had to trim the studs to get everything to fit. I did the same to the passenger side, but I would not if I doing it over, as it is not necessary.

Fitting the baffling was the most baffling. It took several weeks to figure out what to do and how the shaping of the aluminum should be done. Again, trying to use an existing cowling with existing cooling holes (a smiley face inlet) made the job more difficult. I believe using a new cowl and repositioning the inlet holes would make a more efficient cooling system.

Once the installation was complete and I started flying behind this engine, I was pleased with its performance. I was seeing 1000 FPM climb at 115 mph indicated and was cruising at 158 mph indicated at 23" of manifold pressure.

My vacuum gauge needle was bouncing and I was told it was probably due to an intake leak. We checked for leaks and couldn't find any. After some research, we found that the Type 4 lifter springs were stiffer than the Type 1 springs. Steve made a call to his head shop and they used the springs that they use on Type 1 heads. So, we went on a search for Type 4 lifter springs. They weren't easy to find, but we found them and we switched springs. This did nothing to solve my bouncing vacuum needle, but that's when I started having noisy hydraulic lifters. I also found the retaining clip on the #4 exhaust lifter would be bent and come out. Apparently the lifter was bleed down and was not pumping up quickly after start up. This caused two very anxious flights. Just after take off on both flights I lost power and had a noisy engine like a hydraulic lifter or lifters weren't pumped up. I made it back to the field but nothing I did fixed the lifter issue. I had to replace the #4 exhaust lifter three times due to the bent retaining clip. No, they don't just sell the retaining clips!

I had a leaky front seal that I wanted to fix. So I got Steve to come out and help me remove the prop hub and replace the front seal. This event had a profound effect on what was to occur ten hours later. But more on that later.

While we were at it, I had Steve help me put the original lifter springs back in the heads because I did not have lifter issues before we replaced them.

Everything seemed fine after this work was done. I did still have some lifter issues, but they seem to be manageable if you warm the engine up. I have also found that my engine may come to a stop with the #4 exhaust valve open. I try to rotate the propeller one half turn after a flight to close that valve and take the pressure off the lifter in hopes it will not bleed down.

After all this, my vacuum gauge needle still bounced. I decided to switch to a manifold pressure gauge as this was a more conventional power setting device in an airplane. While reading the installation instructions for this instrument, it stated that if the needle bounced, it may be caused by having a too large of opening in the feed from the intake system. A thought occurred to me after I read this and I reach under the panel while the engine was running and squeezed the soft rubber tube feeding the manifold pressure gauge and the needle stopped bouncing. I simply put a cable tie around the rubber tube and pinched it till the needle was steady. Boy, I went a long distance for that resolution.

At this point in my flying, I was starting to stretch my wings and went to my first Fly-in in Yankton SD. After the fly-in I flew to Norfork NE to help the ground crew fly some young eagles. After I returned home I had logged about 3 hours that day.

That was a Sunday, two weeks before Ottawa 2002. The following Wednesday I had my A&P out to sign my log book for my annual condition inspection. The inspection went fine and soon I had the necessary signature and away went my friendly A&P I had 2 hours to go before I needed to change the oil and was fussing with myself about whether I should change it while the cowl was off, or try to fly that coming weekend. Someone was looking out for me, as I chose to change the oil. Once the oil was changed I started the engine to check for leaks. The engine ran rough like the hydraulic lifters were empty. I ran the engine for a while to let the engine warm up in hopes that the lifters would fill up. After awhile I shut the engine down and went to air the tires up. Then I restarted the engine. It ran smooth this time and I was about to shut down and put it away when I decided to make sure it would run smooth at full throttle. That's when I got the shock of my life.

I went to full throttle and then all of a sudden the engine over rev'ed, so I pulled back the throttle and looked up to say to myself, "I don't think I have a prop any more".

To be continued...

(don't you just hate when that happens???)

You can order a printed copy of Q-talk #109 by using the Q-talk Back Issue Order Page.

- Details

-

Category: Q-Talk Articles

-

Published: Wednesday, 23 December 2009 16:24

-

Written by Doug Humble

-

Hits: 3107

It's a new beginning.

I would like to thank you guys for allowing me to be the editor for the last five years. It was never really a chore. My goal was to last for four years and I have made it five. It was fun and challenging to do this. I made friends a long the way that should last a lifetime.

I would like to thank my wife Leeann for proof reading most of the newsletters for me over the last five years. Most of you know how important it is to have your spouse on board with these kind of projects and Leeann has always let me do this "airplane thing". She classifies her memories of our relationship as "before airplane" and "after airplane". She has made it to AirVenture twice now and says once every ten years is good for her.

Most of you know that I have a new airplane project that I'm working on and that I am trying to sell my Q2. That doesn't mean you are through with me, as I will be hosting the 20th Annual Field of Dreams in the Fall of 2010, once again at Beatrice, Nebraska.

Whether you like it or not, I'm not really going anywhere.

Good luck on those projects!

Yours truly, Hawkeye

You can order a printed copy of Q-talk #138 by using the Q-talk Back Issue Order Page.