Q1 Plans Chapter 10 Page 10-7

- Details

- Category: Quickie Plans

- Published: Thursday, 11 September 2008 01:00

- Written by Dan Yager

- Hits: 2376

INSTALLING THE ELEVATOR SLOT FOAM CORES

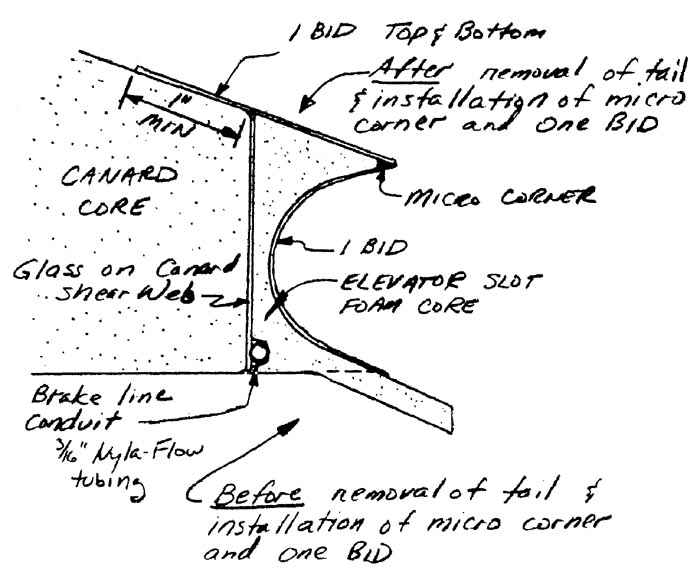

Before installing the elevator slot foam cores to the canard core shear web, dig out for, and micro in place, the 3/16” diam brake line conduit. Allow it to overhang each end by about 8-10”.

The installation will be easier if the canard is jigged vertically.

After mounting, the inboard end of the elevator slot foam core should be no further outboard than BL10.2

Review the section of the main wing plans on TRIMMING THE FOAM CORE as it applies to sanding down the “tails”. Do that with the elevator slots, including the micro corner, and then layup one BID top and bottom to join the elevator slot foam cores to the main portion of the canard. Lap the BID a minimum of 1” onto the main canard skin.

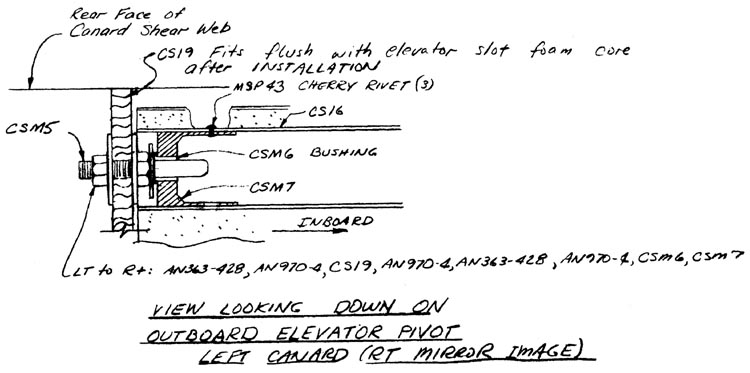

MOUNTING THE OUTBOARD ELEVATOR PIVOT

Find CSM7 and locate it about 0.25” inboard from the outboard end of CS16. Use 3 pop rivets to hold it in position.

Find CS19, and insert CSM5 as shown with the three washers and the AN363-428 nuts. There must be a minimum of 0.6” from the last washer to the end of CSM5 so that CS16 will have to be moved inboard quite a ways before it can fall off CSM5. Round the end of CSM5 as shown.

Later, when C519 is installed against the canard shear web permanently, the elevator slot foam core will be trimmed span- wise so that CS19 will fit flush against the end of it.