Q-talk 133 - Replacing A Broken Mid-span Elevator Pivot Pin

- Details

- Category: Q-Talk Articles

- Published: Wednesday, 23 December 2009 16:24

- Written by Jon Finley

- Hits: 3234

As part of pre-flight I always put one hand on the top and one on the bottom and try to move the elevator up and down at the mid-span and outer pivots. While doing this, the right side mid-span pivot felt very wrong. There are times like these in life that I really hate. There is only ONE possible next step - that is to remove the elevators for a look-see. However; I like to play mental games with myself for a few hours first just to see if I can dream up a less painful option. I couldn't so off came the elevators.

Much to my surprise; the right side mid-span pivot pin (QCSM3) was BROKEN.

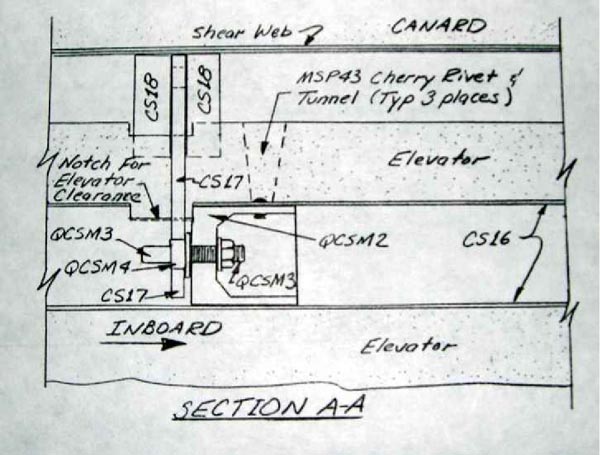

Referring to the Q2 plans diagram on page 10-8, QCSM3 broke just as it exits QCSM2 on the end opposite the nut. I asked a metallurgist friend to take a look at the broken QCSM3. He felt that QCSM3 had been treated very roughly on installation as the threads were stretched. He did not detect any indications of fatigue or corrosion, rather; it appears to have just snapped off. I am not sure what QCSM3 started its life out as (what QAC made these parts from) but I do not think it was AN hardware due to the length of thread on QCSM3. What could cause such a break?? I have no idea. My home runway is quite bumpy (lots of cracks) and I do occasionally like to test the integrity of the asphalt by slamming my plane down onto it to ensure that the asphalt doesn't collapse. So, it is entirely possible that one of these tests caused the problem.

I am not a patient person nor am I a watch maker. Repairing this thing took several years off my life due to working in such tight quarters. All I know for sure is that the elevator is lucky that I didn't pitch it into the street and kick it down the block... To repair, I found an appropriately long AN3 bolt and cut off/rounded the head. Working thru the elevator slot for CS18 with great care and patience, I was able to get the new QCSM3 thread started and turned into QCSM2. Just talking about it causes the pain to well up inside of me!! Due to the limited thread length on a standard AN3 bolt, there was not enough thread protruding thru QCSM2 to use a standard lock nut so I used an MS21043 Hex Nut. This was inserted into a socket and fed up into the elevator torque tube on a VERY long extension. With great patience, I was able to get the nut started on the new QCSM3. The break occurred at just over 600 hrs TT. I now have about 17 hours on the repair and all is well. In hindsight, I am glad that it was QCSM3 that broke instead of CS17 which would have been a more involved repair. I did contemplate using an AN4 bolt for QCSM3 but did not for two reasons. A failure of these parts is extremely rare and trying to drill and re-thread QCSM2 thru that tiny elevator slot core would have driven me insane!

You can order a printed copy of Q-talk #133 by using the Q-talk Back Issue Order Page.