Q-talk 98 - Quick Countersink

- Details

- Category: Q-Talk Articles

- Published: Wednesday, 23 December 2009 16:24

- Written by Dave Richardson

- Hits: 2825

There are times when you need to cut a countersink in fiberglass or wood to accept a flat-headed or bevel-headed screw Since most aviation bevel-headed screw s arc made w ith the bevel at 100 degrees, you w ill need a countersink tool that cuts at 100 degrees. Hardware store. 82 degree, countersinks do not work very well. If you try to just use a larger drill bit. you may remove loo much material and find it is at an improper angle to assure good contact. At Sun 'n Fun and Oshkosh you can always find used production Microstop Countersinks for under $20 and used thread-in countersink cutters for a couple of dollars. Many of these cutlers have a pilot shaft at the tip of the cutter to follow the hole drilled. This helps to keep the cutter centered as you cut out the countersink. You can usually find them with pilots for typical screws used.

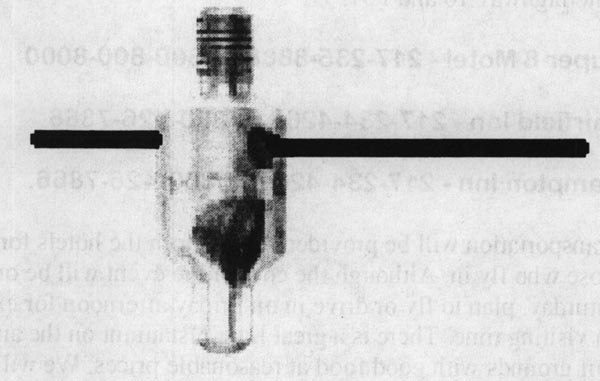

If the w orkspace is limited, it may not be possible to use the w hole Microstop Countersink tool along with your drill. You can use only the screw -in cutter if you take advantage of the hole used to tighten the cutter into the countersink tool. When looking at the side of the cutter's barrel section between the threaded end and the cutting surfaces, you will see a small hole through the barrel. If you insert the shaft of a properly sized drill bit tlirough that hole, you now have some leverage to mm the cutter by hand and countersink your material. You could even take this idea up another notch by tapping a J/i-28 thread (same as an AN-4 bolt) into a handle or a knob to accept the threaded portion of the cutter to make vour own hand tool.

You can order a printed copy of Q-talk #98 by using the Q-talk Back Issue Order Page.